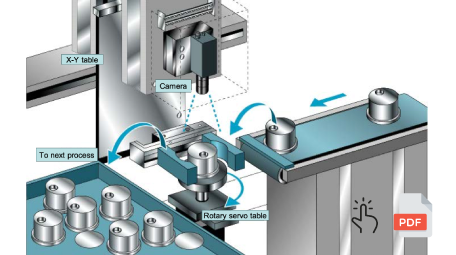

The Definitive, Problem-Free Solution in Alignment Applications

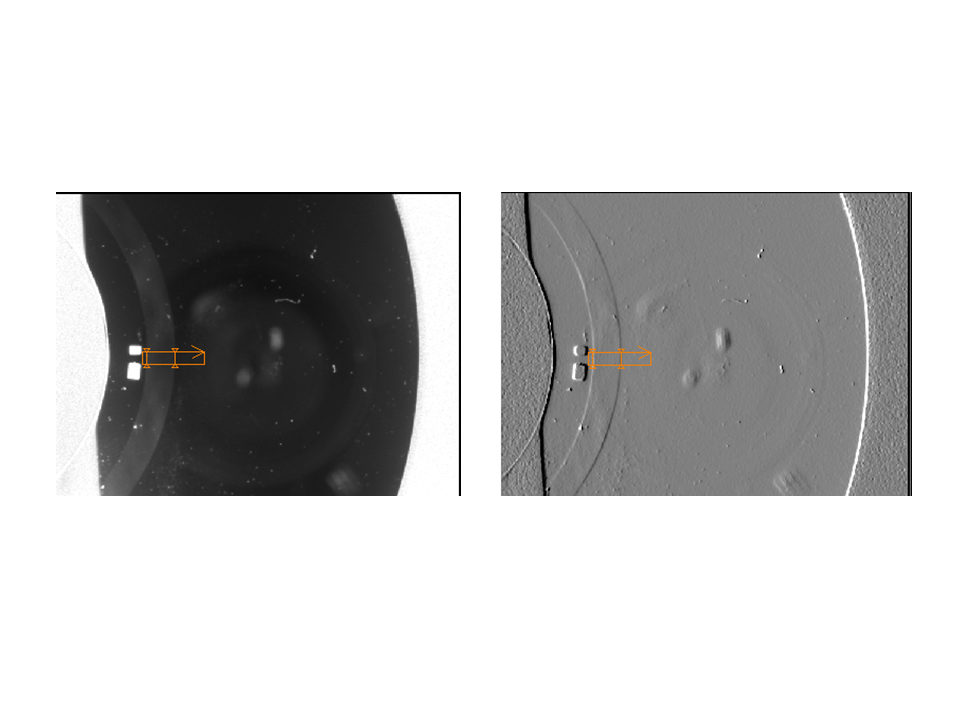

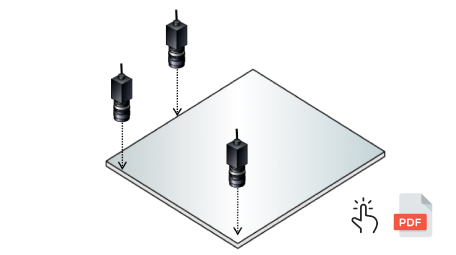

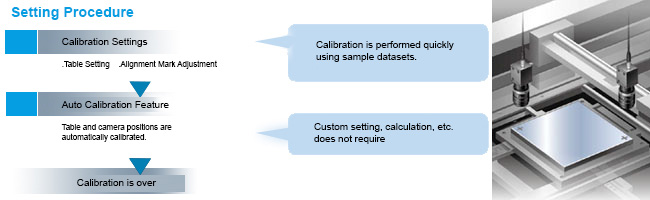

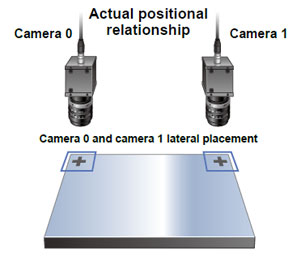

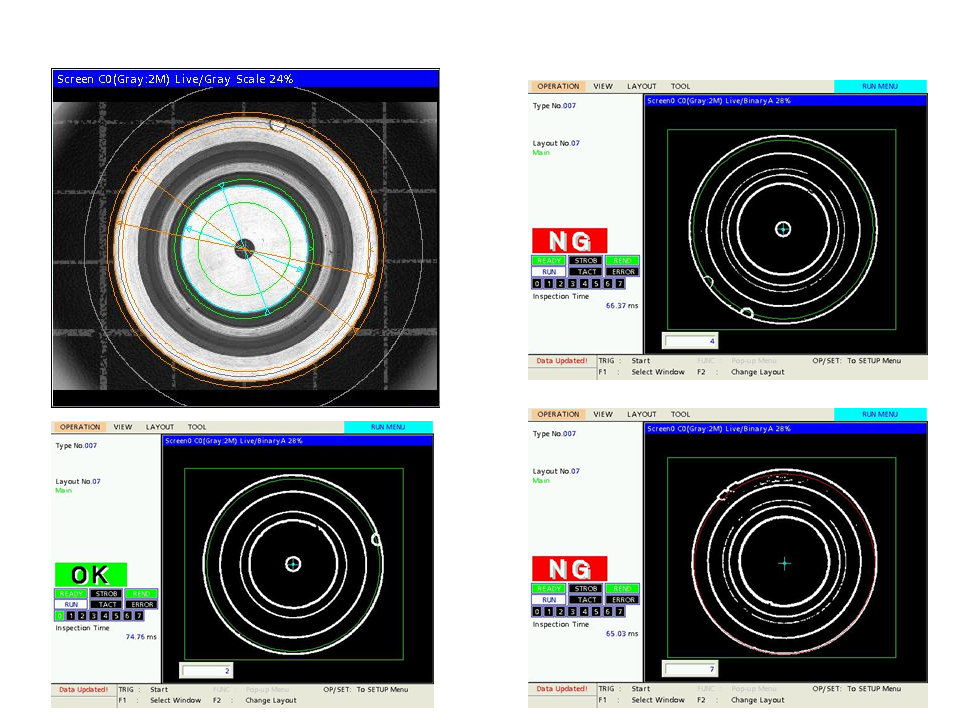

Auto Calibration

Calibration is performed automatically after the edge mark used for alignment is displayed. Differences between two separate camera views, such as the rotational taper, are also automatically corrected.

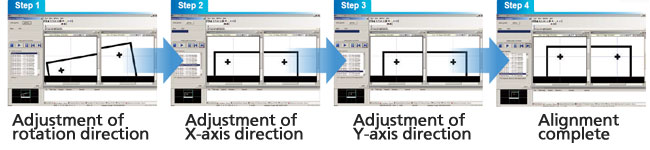

Visual Calibration

The result of automatic calibration can be monitored visually on the screen and be sure of its accuracy.

Simulation

The entire alignment and calibration process can be simulated step by step on the PVWIN240 program.

-

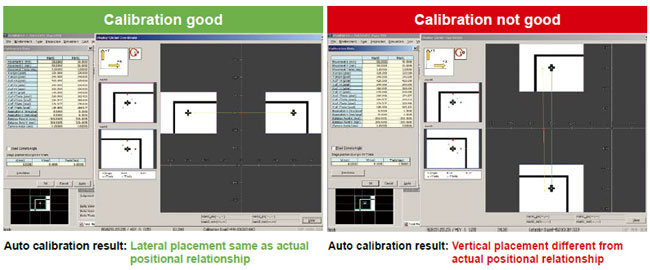

Broken/Missing Medicine Tablet Control

-

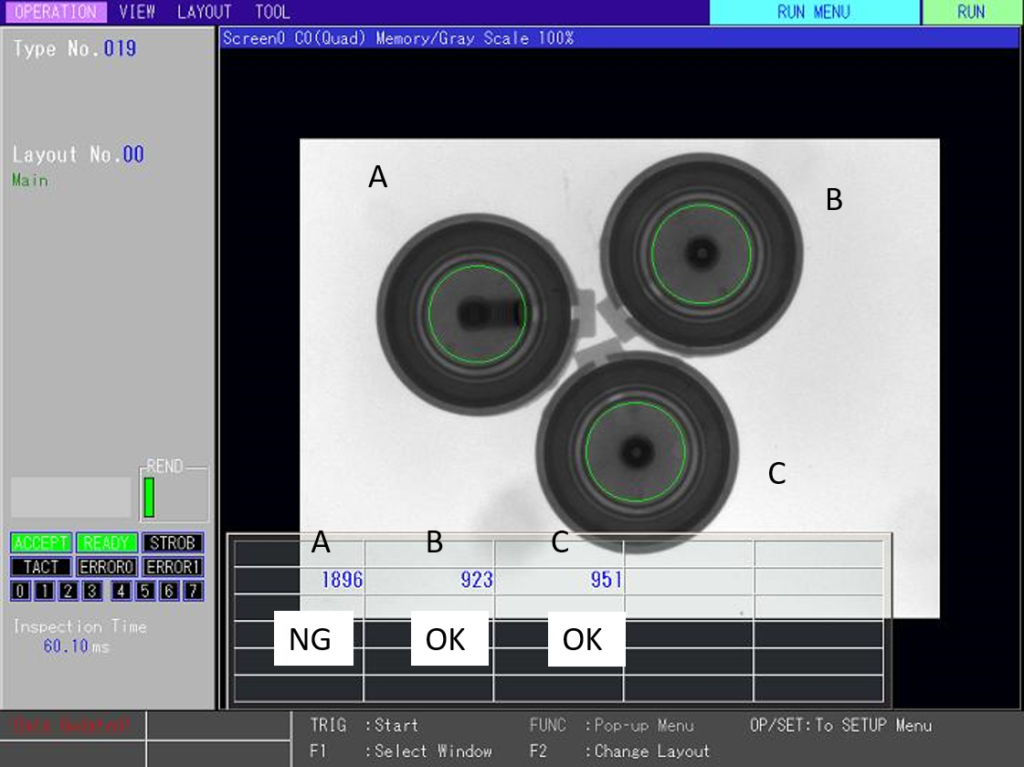

Pin pattern check inside the connector

-

Crack and dust particle control on the rubber cover

-

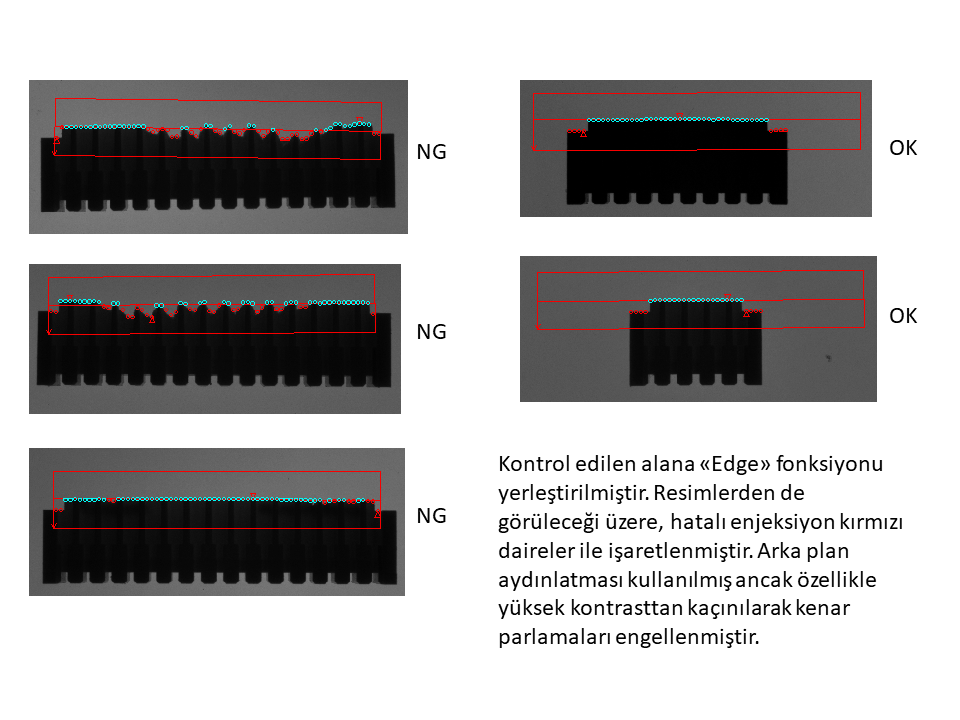

Precise injection error check on connector

-

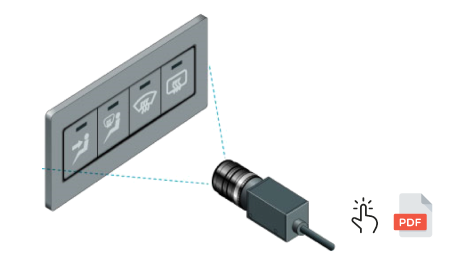

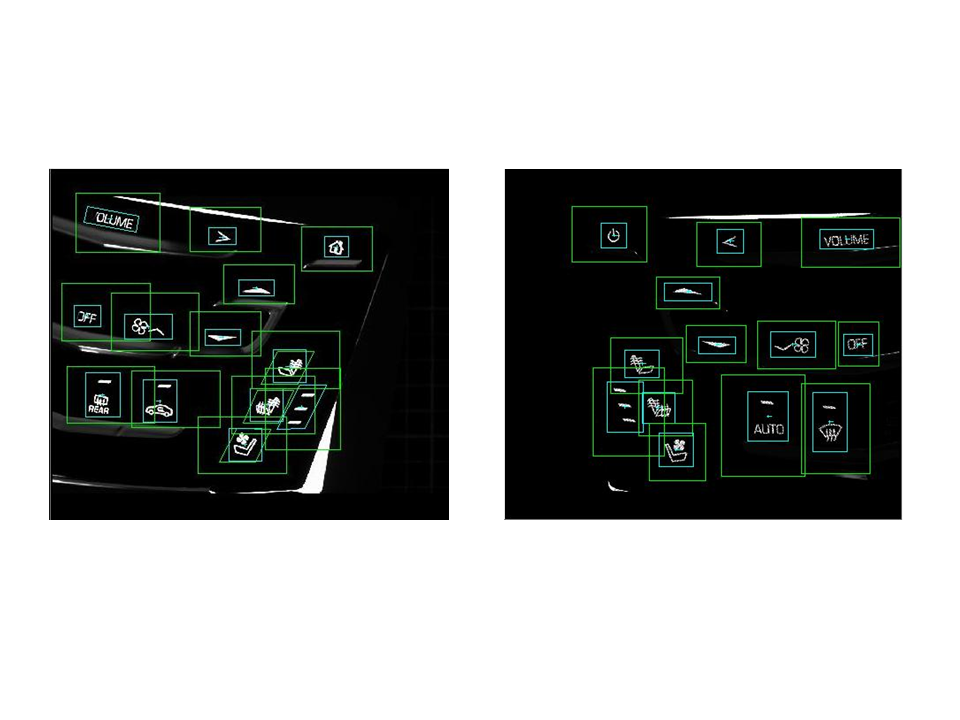

Accuracy and angle control of button labels on the dashboard of the automobile

-

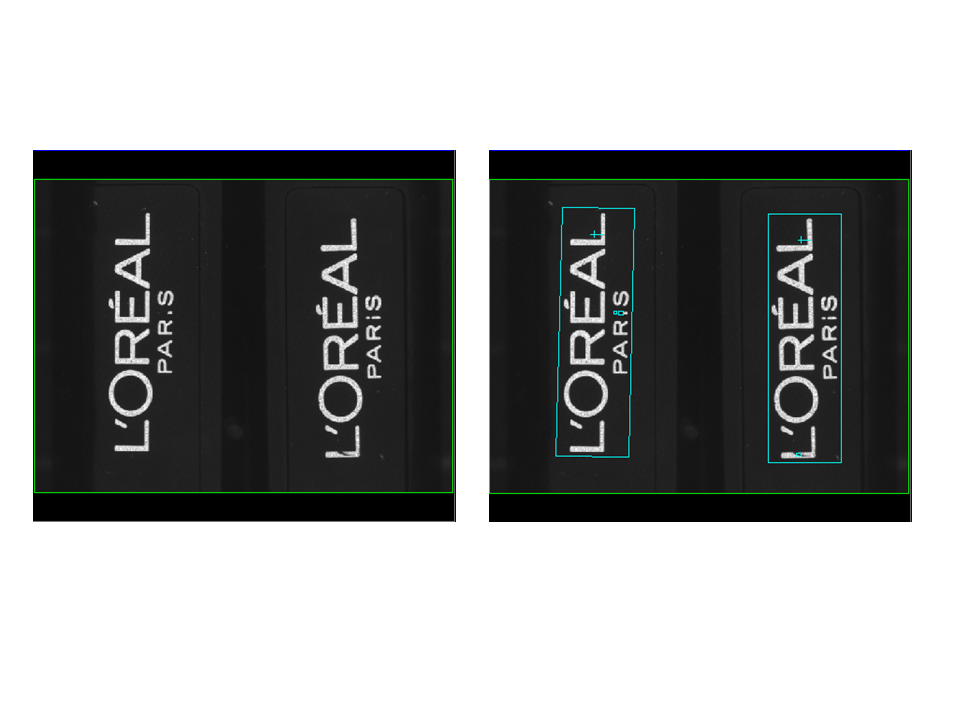

Incorrect character control on the label on the product

-

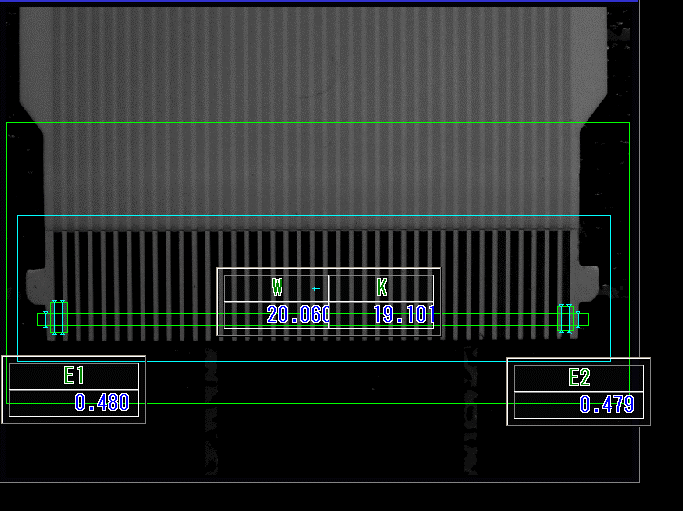

Size control in data cable production

-

Notch singularity check on the metal part

-

Presence, absence and alignment control of springs placed in the part

-

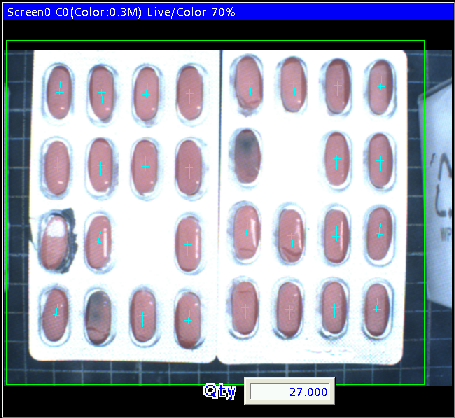

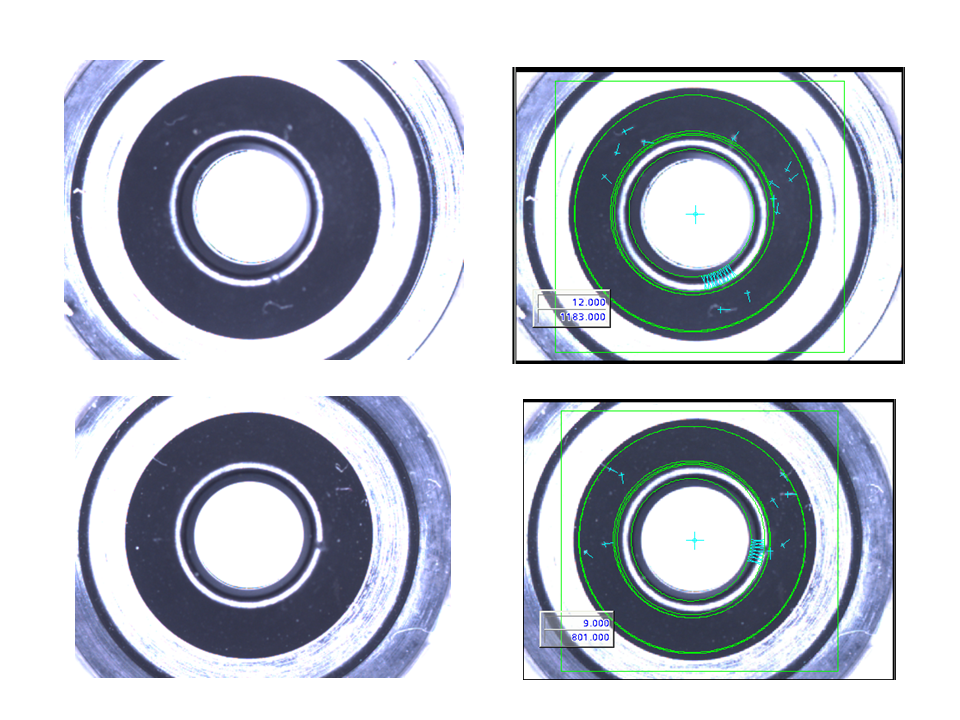

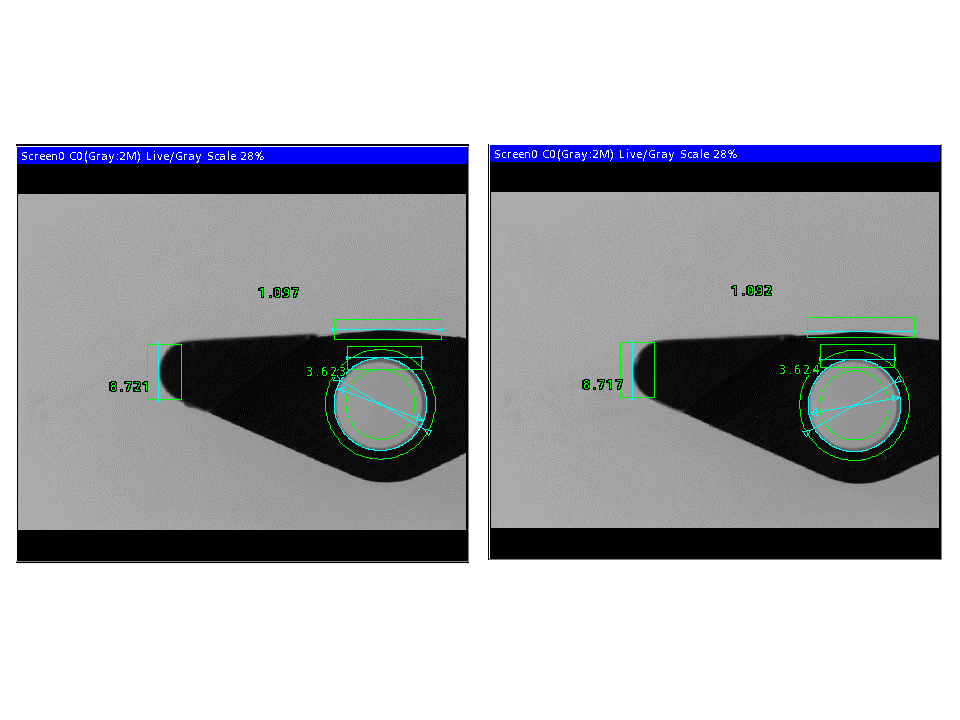

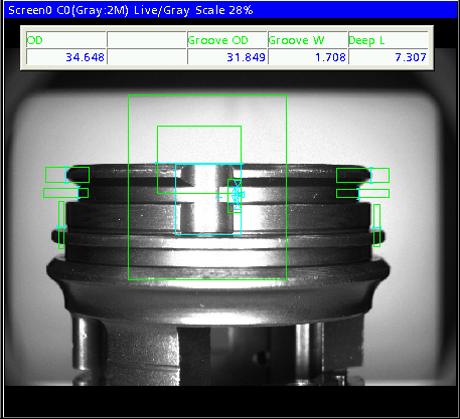

Micron level dimensional control on gear

-

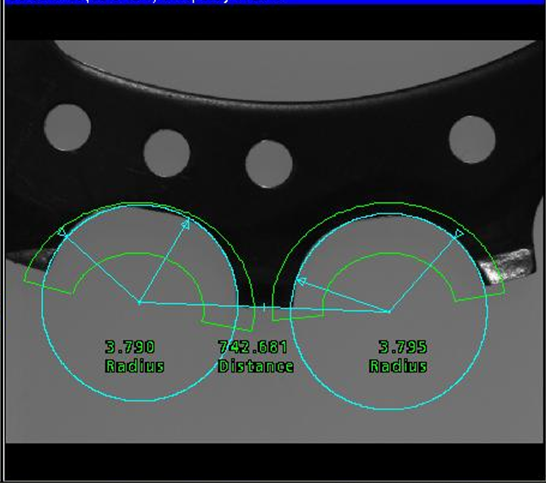

Micron level dimensional control on the metal part

-

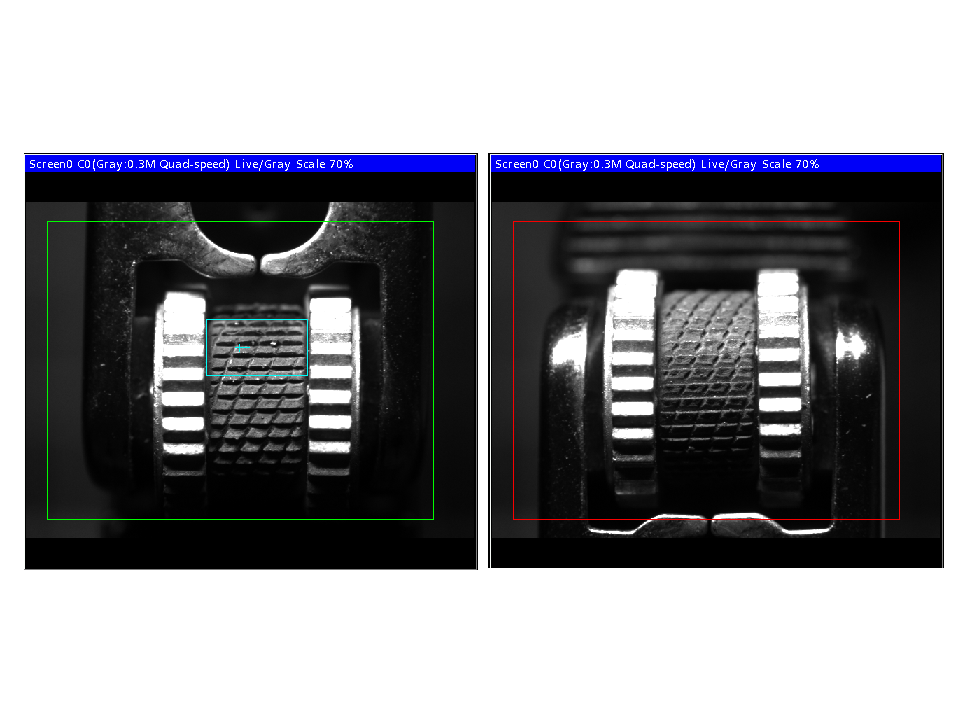

Micron-level dimensional control over the bicycle part

-

Gear direction control in cigarette lighter assembly

-

Trace presence / absence and size control of 40 Angstroms (1 Angstrom = 0.0000001mm (10 millionth of a millimeter)