1 – AUTOMATIC CALIBRATION

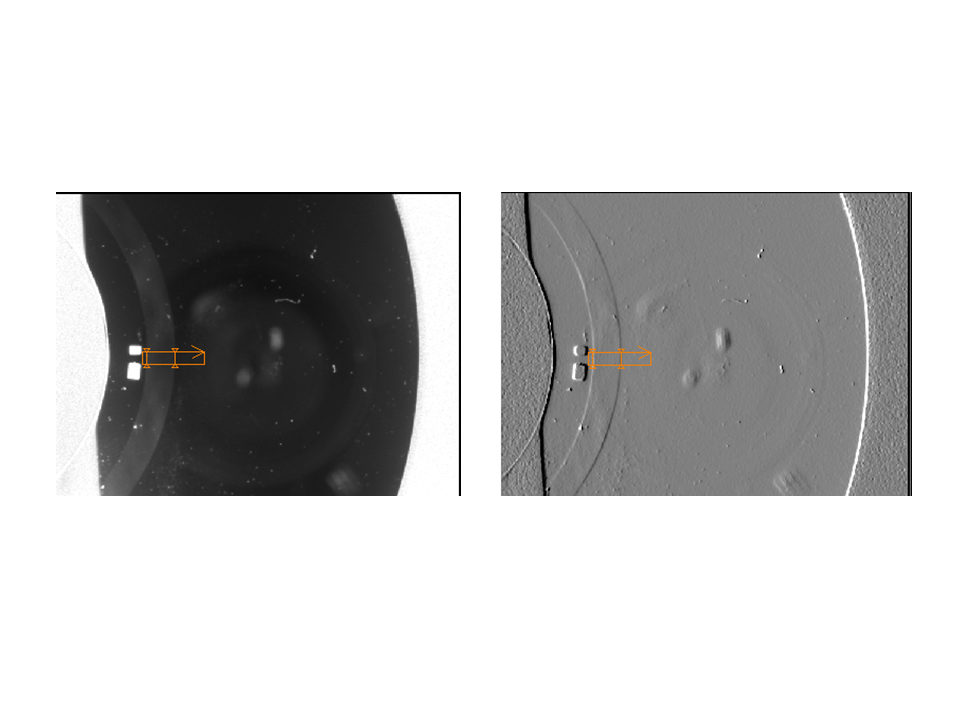

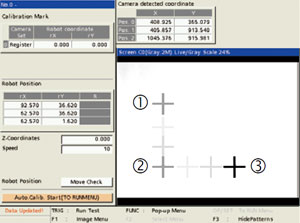

By specifying only 3 or 4 points, the camera coordinate system is synchronized with the robot coordinate system.

|

Advantages

|

4 functions to minimize robot calibration time!

By specifying only 3 or 4 points, the camera coordinate system is synchronized with the robot coordinate system.

|

Advantages

|

Unlike the old position teaching techniques using the robot controller, industrial robots can now be moved and taught using the PV260 camera controller.

|

Advantages

|

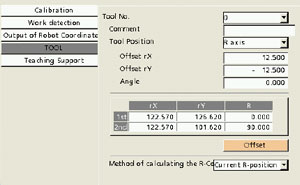

By teaching only 2 points on the robot hand connected to the robot, the Robot Hand coordinate system is automatically calculated and turned into a robot coordinate system.

|

|

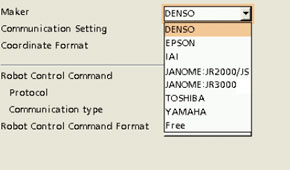

It can communicate with DENSO, EPSON, IAI, JANOME, TOSHIBA, YAMAHA brand robots directly without any settings. For other brands, it is possible to communicate with only a few settings by selecting the Free mode. In this way, PLC programming time is significantly shortened.

|

|