Yüksek performanslı parça besleme, ön yönlendirme (pre-orientation), dökme parçaların ve bileşenlerin optimum yüzey dağılımını sunar.

ASYRIL

Besleyici Sistemler – 3 Eksenli Titreşim Teknolojisi

Asyril’ in ödüllü Asycube esnek besleyici serisi;

- yüksek performanslı parça besleme

- ön yönlendirme (pre-orientation)

- dökme parçaların ve bileşenlerin optimum yüzey dağılımını sunar

Asycube Avantajları

- Tüm parça geometrileri ile uyumlu: Karmaşık geometriler ve hassas malzemeler dahil olmak üzere parçaların % 99’u besleyicilerimizden beslenebilir.

- Minimum üretim değişim süreleri esnek, geleceğe yönelik üretim sistemlerine olanak tanır.

- 3 eksenli titreşim teknolojisi sayesinde son derece hassas parça işleme: parçalar, her parça için en uygun döndürme genliği seçimi dahil olmak üzere tüm yönlerde hareket ettirilebilir. Platform temizliği mümkündür.

- Manyetik aktütörler sayesinde gelişmiş güvenilirlik ve dayanıklılık; basınçlı hava kullanımı yoktur.

- Entegre ayarlanabilir arka ışık sayesinde hassas parça algılama

- Asyril’ in Besleyici Kontrol Merkezi Yazılımıyla kolay konfigürasyon

- En popüler robot markaları ile çok sayıda yazılım eklentisi sayesinde basit sistem entegrasyonu

- Standart iletişim protokolleri (TCP-IP, Modbus) tabanlı tüm otomasyon sistemleri ile basit iletişim

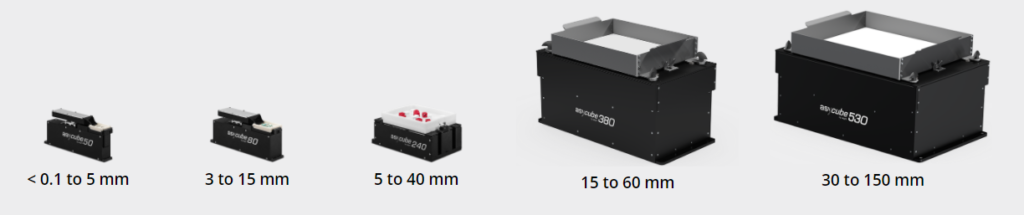

Besleyici Ürün Aralığı

Asycube 50

0,1-5 mm yassı ve küp benzeri küçük parçalar ve 10 mm’ ye kadar uzun parçalar için (örn. çivi ve iğne) ideal besleyici

Boyutları

Titreşimli Platform:

45 x 34 mm; ~50 mm diyagonal

1.3 x 1.8 in; ~2 in diyagonal

Besleyici (L x W x H):

293 x 46 x 138 mm

11.5 x 1.8 x 5.4 in

Besleme Haznesi:

10 cm3 / 110 cm3

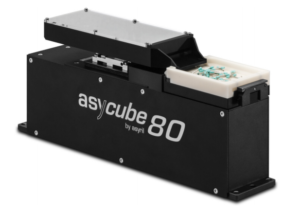

Asycube 80

3-10 mm yassı ve küp benzeri küçük parçalar ve 15 mm’ ye kadar uzun parçalar için (örn. çivi ve iğne) ideal besleyici

Boyutları

Titreşimli Platform:

65 x 52 mm; ~80 mm diyagonal

2.6 x 2.1 in; ~3.1 in diyagonal

Besleyici (L x W x H):

320 x 61 x 138 mm

12.6 x 2.4 x 5.4 in

Besleme Haznesi:

160 cm3

Asycube 240

5-40 mm yassı ve küp benzeri küçük parçalar ve 50mm’ ye kadar uzun parçalar için (örn. çivi ve iğne) ideal besleyici

Boyutları

Titreşimli Platform:

195 x 150 mm; ~240 mm diyagonal

7.6 x 5.9 in; ~10 in diyagonal

Besleyici (L x W x H):

300 x 171 x 132 mm

11.8 x 6.7 x 5.2 in

Besleme Haznesi:

2 litre/ 3 litre

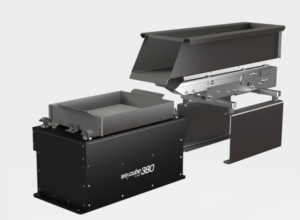

Asycube 380

15 ila 60 mm arasındaki bileşenler için ideal besleyici

Boyutları

Titreşimli Platform:

254 x 325 mm; ~380 mm diyagonal

10 x 12.8 in; ~14.96 in diyagonal

Besleyici(L x W x H):

499 x 257 x 307 mm

19.6 x 10.1 x 12.1 in

Besleme Haznesi:

10 litre

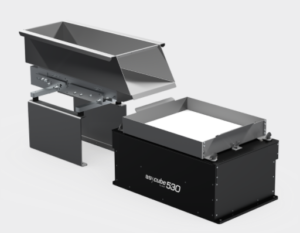

Asycube 530

30 ila 150 mm arasındaki bileşenler için ideal besleyici

Boyutları

Titreşimli Platform:

427 x 371 mm; ~530 mm diyagonal

16.8 x 14.6 in; ~20.9 in diyagonal

Besleyici(L x W x H):

600 x 372 x 320 mm

23.7 x 14.7 x 12.6 in

Besleme Haznesi:

15 litre

Asycube Clean 230

Hijyenik uygulamalar için esnek besleyici

Boyutları

Titreşimli platform: 230 mm (Çapraz)

Genel boyutlar:

Genişlik: 177,5 mm, uzunluk: 237,5 mm

Uyumlu parça boyutları: 5 – 40 mm

Özellikleri

Özellikle temiz oda ve farmasötik ortamlar için tasarlanan Asycube Clean 230, en katı GMP Ek1 gerekliliklerini karşılamak üzere tasarlanmış ilk esnek besleyicidir. 190 Hızlı Transfer Portuna (RTP) sığacak kadar kompakt olan sterilize edilebilir plakası ve kimyasallara dayanıklı tasarımı, robotize izolatörlere ve aseptik bölgelere sorunsuz entegrasyon sağlar.

Geleneksel kase besleyicilerden farklı olarak, Asycube Clean 230 eşsiz bir esneklik sunar: özel takım gerektirmez, daha hızlı geçişler ve küçük partiler ve kişiselleştirilmiş sağlık hizmetleri için tam uyarlanabilirdir.

Asycube Clean 230 Asyril’in patentli 3 eksenli titreşim teknolojisine sahip olup, Eye+ Akıllı Kontrol Sistemi ile kusursuz bir şekilde çalışarak hızlı ve doğru parça tespiti sağlar.

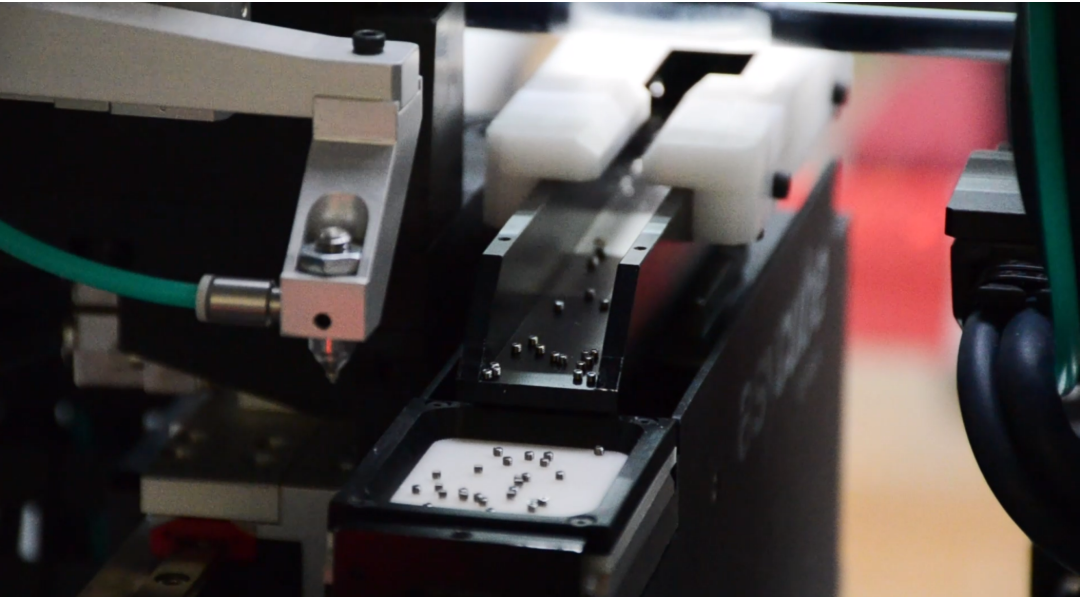

Installation of prosthetic dental implants

Prosthetic dental implants must meet the highest standards of quality and flexibility. Because every dental implant is unique, product migration from one variant to another must be easy, fast and highly reliable.

-

Read More

During the feeding and precision assembly process, it is imperative to guarantee and maintain the flawless finishing of precision parts to avoid any risk of injury.

Advanced Technologies, a subsidiary of Dentsply Sirona, has created a flexible assembly machine to manufacture different types of denture implants.

Two Asycube 80s with platforms configured to properly route components; an Asycube 50 for feeding small screws; and an Asyril SmartSight intelligent vision system, which includes an intuitive HMI, easy communication with PLC, and seamless recipe management.

Installation of fiber optic connectors

The full range of Radiall optical connectors includes not only standard products, but also several customized items. That’s why Radiall constantly strives for greater flexibility in its automated assembly processes, allowing its operators to focus on more value-added tasks.

-

Read More

Designed for demanding applications where reliability and high performance are indispensable, Radiall fiber optic connectors must not be damaged during the assembly process.

Radiall has developed an in-house manufacturing system that is both flexible and collaborative to facilitate automated assembly of fiber optic connectors.

The system consists of two Asycube 80s (feeding the ferrule and the ferrule holder, respectively).

A collaborative YuMi® ABB robot takes two components and places them under a press for assembly.