- VISOR® XE

- VISOR® Object AI

- VISOR® Object

- VISOR® Robotic +Z

- VISOR® Robotic

- VISOR® Code Reader

- VISOR® Solar

- VISOR® Color

- VISOR® Allround

VISOR® XE – the extra-fast vision sensors

Discover our VISOR® XE product series and experience the future of industrial image processing. With integrated deep learning optimisation, simplified installation and multiple processor cores, these sensors excel in object detection - delivering results four times faster than their predecessors.

The innovative vision camera masters demanding tasks with precision and flexibly, even with changing working distances and varying requirements. Take a closer look at our new product generation and let VISOR® XE elevate your production processes to a new level.

Advantages of our new vision sensors

- Four times faster: higher processing speed than previous models.

- AI power: eight times faster classification for more precise results.

- Simple system integration: additional communication plug for simplified installation.

- Maximum compatibility: work seamlessly with existing VISOR® software and accessories.

- Universally applicable: versatile for multiple tasks, e.g. as a code reader and for robot-guided applications.

VISOR® XE: Features at a glance

With the VISOR® XE series, we are expanding our proven vision sensor portfolio with a proven a future-proof, optimized hardware platform that is also equipped for continuing advancements in image processing and artificial intelligence. VISOR® XE sensors are more powerful and faster than their predecessors. They are also flexible, easily adapting to varying working distances, facilitating the precise detection and processing of objects. Thanks to their advanced technology and effortless integration into existing systems, VISOR® XE sensors are the ideal solution for demanding applications that require fast and precision-driven results.

Our VISOR® XE series is well suited for a wide range of applications in production automation - from simple presence and completeness checks to complex quality control. This makes this new generation of vision sensors a smart investment that delivers lasting value and fast returns.

We offer vision sensors in a variety of models, ensuring the perfect fit for your application needs.

- Advanced: with an extended range of functions to support complex requirements

- Professional: comprehensive measuring system for demanding applications

Maximum performance with advanced technology

VISOR® XE sets new standards in industrial image processing: the sensors work up to four times faster than conventional vision sensors and boost object classification speed times eight - thanks to a processor with integrated hardware acceleration for deep learning algorithms. We achieve this substantial performance increase by optimizing the use of several processor cores working in tandem.

For you, this means faster image processing and increased productivity, even for tasks that are complex and require high resolution. Supported by artificial intelligence, the VISOR® XE sensors excel in detecting even the smallest details in large image fields. This makes the series ideal for applications that require maximum precision and speed.

Seamless integration into your operation

The installation and deployment of VISOR® XE sensors is particularly simple and efficient: the additional LAN interface makes it easier to connect multiple vision sensors and reduces the Change to number of cables needed

for applications with several cameras, e.g. in robotics. With a sensor from the VISOR® XE series, a single cable to the robot controller is all you need to integrate multiple cameras, for example - saving you time and money. The sensors in the VISOR® XE series are also fully compatible with existing VISOR® software and interface protocols. This means that you can utilize existing configurations and systems without any time-consuming integrations.

VISOR® XE sensors excel in image processing

Whether precise code detection, reliable object detection or seamless integration into robot applications - the VISOR® XE series offers the right solution for a wide range of industrial applications and sets new standards in Industry 4.0. To meet the specific requirements of diverse areas of application, the sensors are available in different models, each optimized for specific requirements and offer outstanding performance and reliability. This high level of flexibility makes the sensors in the VISOR® XE model series an indispensable tool in many industries, from automotive to packaging.

Application Solution Examples

High-Speed, High-Resolution Code Reading

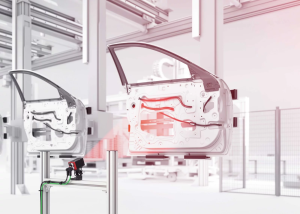

Precise Presence Detection of Car Door Components

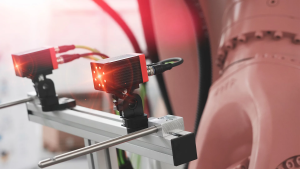

Precise robotic handling for large components

The right VISOR® XE for every application

VISOR ® XE Code Reader

VISOR® XE Robotic

VISOR ® XE Object AI

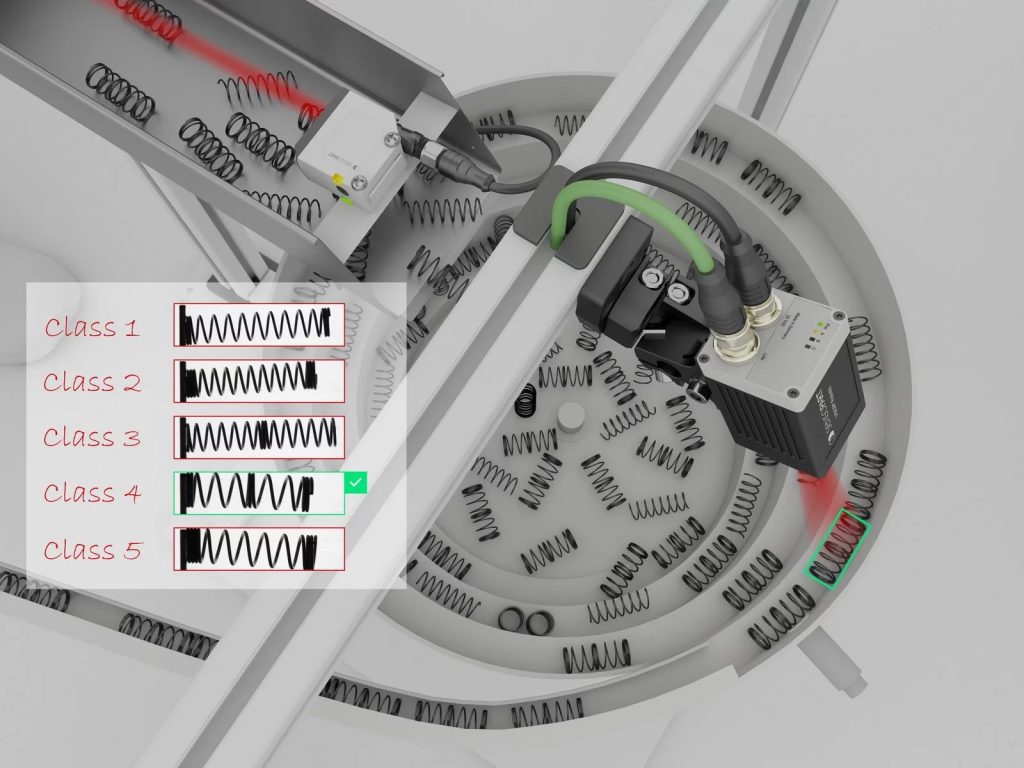

VISOR® Object AI makes machine vision easier than ever before. It has the full flexibility of VISOR® Object Advanced and offers additionally the "Classification (AI)" detector, which makes the classification of objects even easier and more robust.

For presence checks, objects can be evaluated as “pass“/“fail"" or reliably classified into200 classes, e.g. to ensure that the correct product is fed and processed in a machine.

The sensor is set up in just a few steps and requires no expert knowledge. Thanks to integrated artificial intelligence (AI), the detector learns the distinguishing features based on a few sample images. Even process and product variations, such as varied products in lots, stains, strong reflections, flexible parts, etc. can easily be taught to the detector with just a few mouse clicks.

With the classification detector, even very similar looking springs are reliably distinguished and correctly fed to the machine.

Application Example

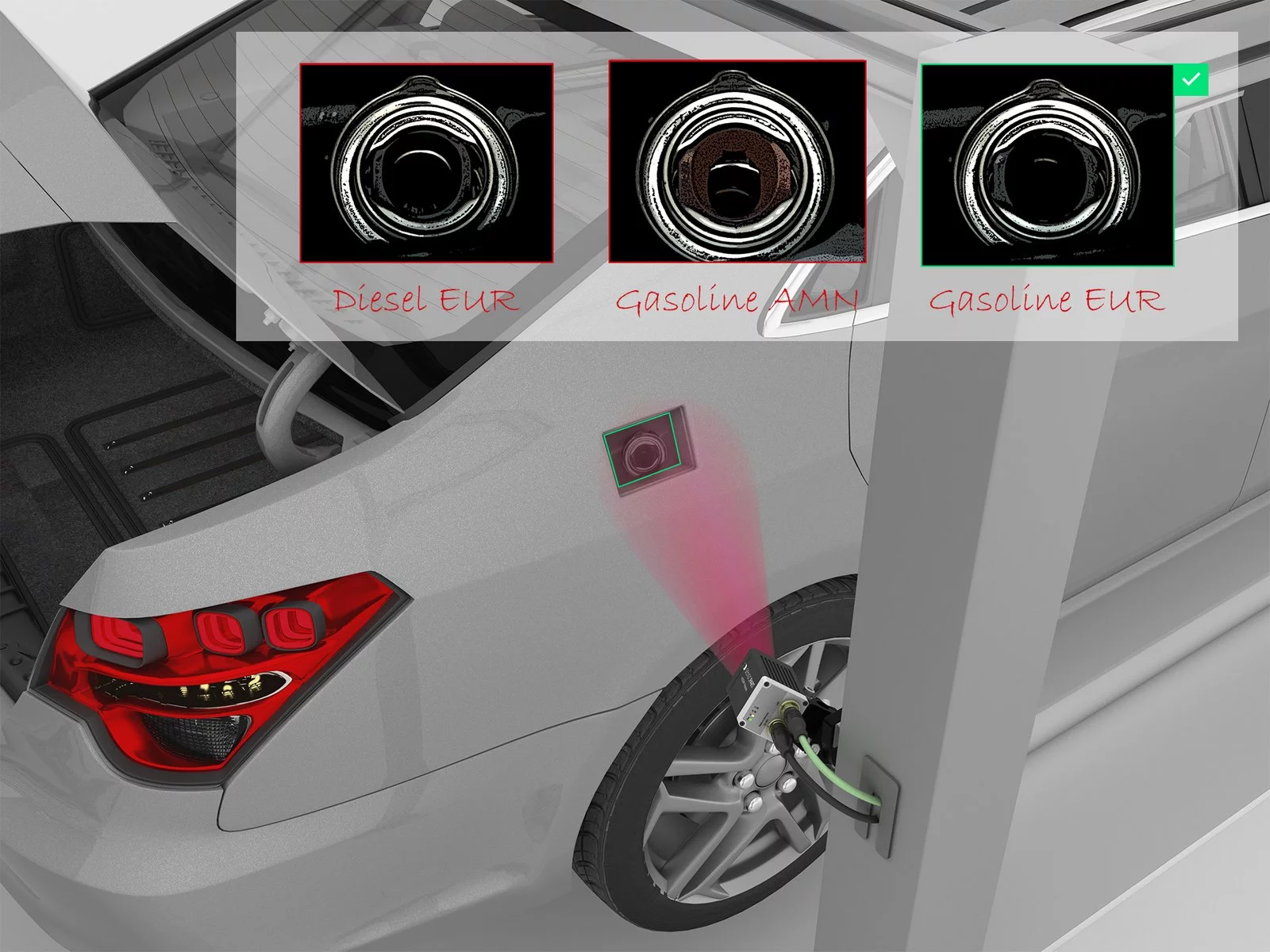

Check the right type of fuel filler necks

The VISOR® Object AI easily checks whether the correct type of fuel filler necks has been installed in the different cars on a production line.

Check the right type of switches on the dashboard

Depending on the chosen additional equipment, a dashboard has different switches, which the classification detector in the VISOR® Object AI reliably distinguishes and checks.

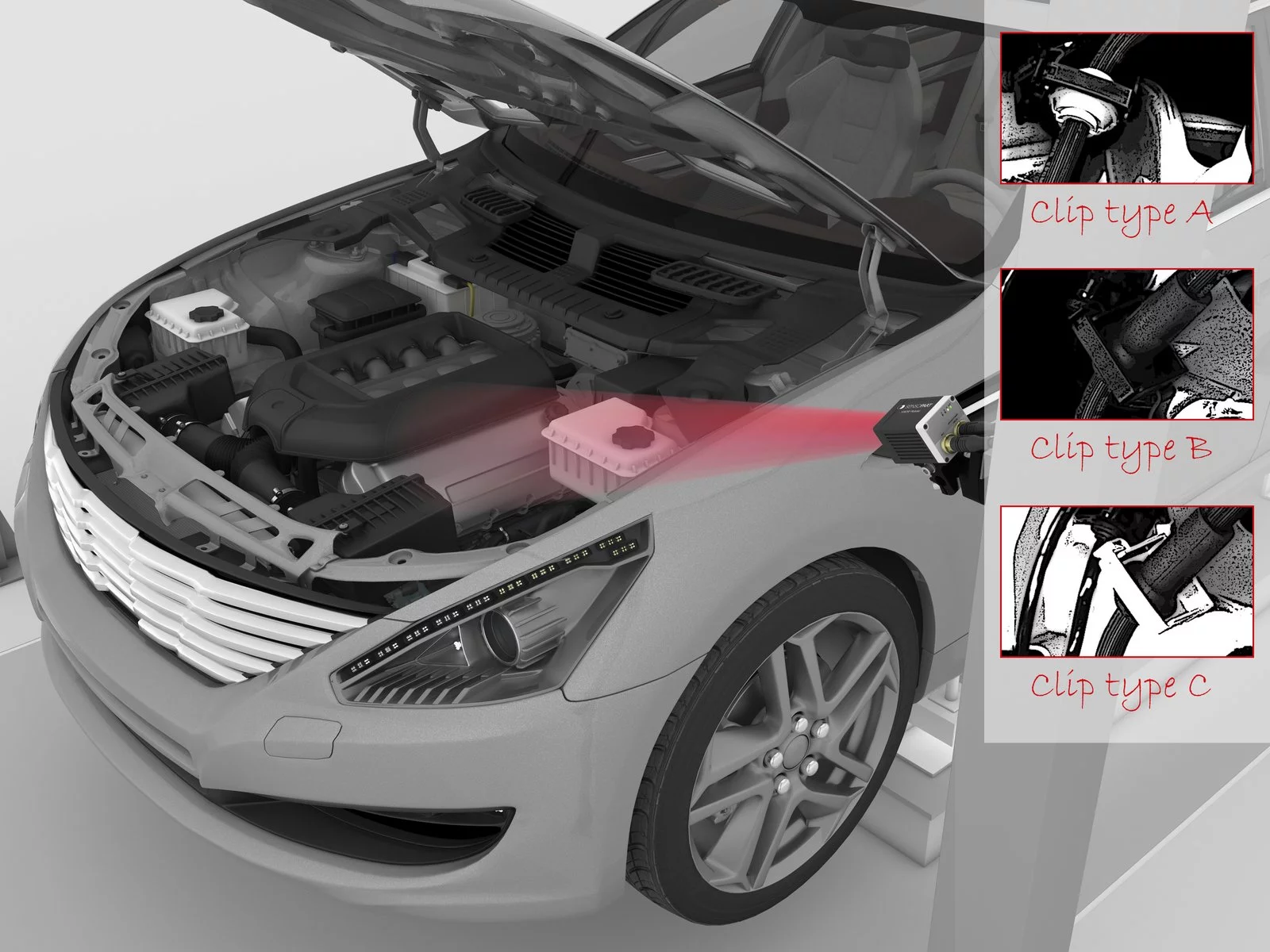

Check the right type of fuel hoses and clips

The VISOR® Object AI detects the different fuel hoses and respective clips in different cars and reliably checks whether the correct ones have been installed.

VISOR® OBJECT

Is the workpiece where it should be?

How does it stand on the conveyor?

Is there a lack of detail on the piece?

Has an error been made during installation?

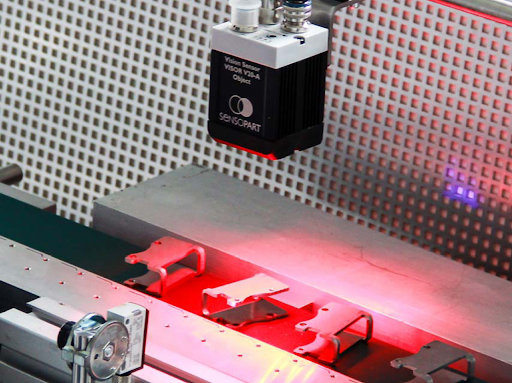

With VISOR® Object Sensor, part position tracking, part components tracking and pick & place operations can be done easily by robotic systems.

- Checker for presence and absence control

- Part finding and position tracking with advanced algorithm

- Precise position finding and coordinating in X / Y cartesian space

- Archiving the data and pictures obtained

Visor Object has 3 different resolutions.

- V50: 5 MP - 2560 x 1936

- V20: 1.5 MP - 1440 x 1080

- V10: 0.5 MP - 800 x 600

Robot Approach Using Depth Information

The VISOR® Robotic +Z is a vision sensor with distance measurement for robot guidance. In addition, object inspections such as presence and completeness

checks and measurement tasks can be performed.

Applications

- Robot approach using depth information

- Positioning

- Object detection

- Measurement

- Identification

255 Jobs with 255 detectors each

- Position tracking X/Y and orientation

- Pattern matching, Contour, Target Mark 3D: teach-in and detection of patterns, contours and 3D poses

- Calliper: distance between edges

- BLOB, Grey, Brightness: evaluation of brightness

- Contrast: evaluation of contrast

- Result processing: Text, Math: checking and calculating with results from detectors

- Distance Point: Distance determination of the VISOR® to an object

VISOR® ROBOTIC

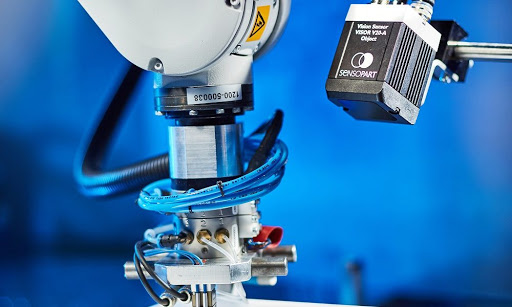

Expectations for today's robotic solutions are increasing in the context of industry 4.0. VISOR® Robotic, on the other hand, offers the perfect solution for a variety of automation tasks. It can be easily incorporated into existing systems with its integrated and standardized interface, and is suitable for various procedures thanks to different calibration methods and flexible data structures. It can provide easy connection with robotic systems from leading manufacturers.

Visor Robotic has 3 different resolutions.

- V50: 5 MP - 2560 x 1936

- V20: 1.5 MP - 1440 x 1080

- V10: 0.5 MP - 800 x 600

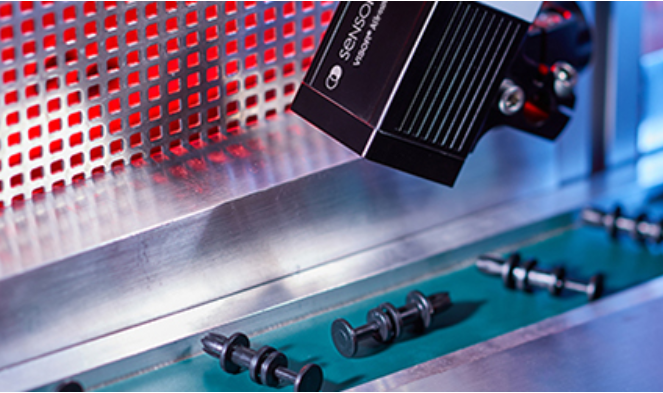

Picking Part

In production, parts can be fed into the lines by using versatile systems such as feeding buckets in addition to the trays (universal tray). Thanks to VISOR® Robotic, parts can be gripped and positioned reliably with either feed option. When the parts are fed, the sensor not only checks their position, but also checks the free space around the holder. VISOR® determines both sets of information and sends them to the robot through its integrated and standardized interface. The object is held or feeder triggered without the need for a costly fixture. At the same time, VISOR® detects the position of the tray and the filling level and transmits this information to the robot.

Placing Part

Once the parts are reliably collected by the gripper, VISOR® Robotic provides important information for next work steps and demonstrates its skills in robot-controlled applications such as inserting screws, mounting clips or applying glue. Detection of part positions is carried out effortlessly. It allows any offset to be corrected and improves the production quality. Mechanical effort is reduced and the production line becomes even more flexible.

The VISOR® Robotic vision sensor announced that it was chosen among the best in artificial vision by the Vision Systems Design 2020 Innovators Awards jury, which reviews the most innovative products and services in the image processing industry.

VISOR® CODE READER

With its automatic object detection feature, it can read 1D, 2D Matrix codes and perform OCR (Text reading - Optical Character Recognition).

VISOR® Code Reader easily reads printed and directly marked data matrix codes as well as multiple bar codes according to the ECC 200 standard regardless of the material (metal, plastic, paper, glass).

- It reads stamped barcodes and QR codes with high reliability.

- Reading text (Optical Characters Recognition)

- Supports ISO / IEC 15415 and AIM DPM 2006 quality parameters

- Automatically detects the code region within the given area

- The syntax read can be compared. (String comparision)

- Output data format adjustable

Visor Code Reader has 3 different resolutions.

- V50: 5 MP - 2560 x 1936

- V20: 1.5 MP - 1440 x 1080

- V10: 0.5 MP - 800 x 600

Scope of Application

Automotive and sub-industry, food and beverage industry, pharmaceutical and cosmetic industries, packaging industry and logistics, solar industry in many different areas such as;

- Product labeling and identification

- Automatic product tracking

- Product collection, quality assurance

Printed barcodes

Laser printed codes on plastic

Dot matrix codes on rough surface

Codes on the glass surface

VISOR® SOLAR

VISOR® Solar is specially designed to maximize quality control processes in solar panel production. It enables robots to pick and place plates accurately during Thin Panel production. It is used to detect cracks and damaged parts. It provides an advantage in robotic system supported production.

- It can accurately identify the position

- Detects the errors that may occur on the edges with high efficiency

- Detects holes that may occur on the panel during production

- It can work efficiently even in daylight

- No backlight needed

- Does not occupy space, can work from a distance of 360 mm

Visor Solar has 3 different resolutions.

- V50: 5 MP - 2560 x 1936

- V20: 1.5 MP - 1440 x 1080

- V10: 0.5 MP - 800 x 600

VISOR® COLOR

It offers a wide range of solutions by combining color properties and position detection features. It can be used to separate products through their colors and shapes. VISOR® Color provides error-free control even for objects that appear in unexpected positions and have complex shapes and details.

Is it the same or a different color?

VISOR® Color detects even the smallest color nuances more reliably than the human eye. This allows for detecting chromatic aberration in parts or classifying parts by color.

Color and object detection in one device

VISOR® Color combines color and object detection in a single device and can therefore simultaneously inspect the medicine package's fullness and whether it is filled with the correct color medication.

Are the LED Lights in the right place?

A unique performance feature of visual color sensors is the perception of active (self-illuminating) colors. For example, screens or electronic components in the automotive industry can be inspected with VISOR® Color for correct placement.

VISOR® ALLROUND

In the VISOR® Allround version, the device combines the functions of the VISOR® Object (calibration, pattern matching, contour, caliper, BLOB) with the tools of the VISOR® Code Reader (barcode, data matrix and optical character recognition).

Additional data matrix codes are now readable when feeding parts or positioning components in a correctly aligned way. With a resolution of up to 5 megapixels, even the smallest details are reliably detected and evaluated.

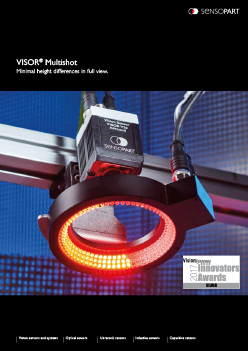

Object details that are raised or indented, such as embossed numbers and characters on a credit card, are difficult to detect with standard image processing methods. Even the use of lateral lighting often results in poorly identifiable contours due to overexposure and shadows. VISOR® Allround Professional corrects this with its new multishot feature.

Powerful color filters for maximum contrast

With the help of powerful color filters that emphasize the relevant area of the image and suppress obstructive image parts, part recognition and code reading can be performed more simply and reliably with maximum contrast.

Visor Allround has 3 different resolutions.

- V50: 5 MP - 2560 x 1936

- V20: 1.5 MP - 1440 x 1080

- V10: 0.5 MP - 800 x 600