The production technologies that have developed with Industry 4.0 have rapidly increased the use of robots in factories and production lines. Today, manufacturers prefer robots that work with high speed, precision and stability. At this point, SCARA robots stand out as one of the most efficient robot types that optimize production processes.

Before moving on to the areas of use of SCARA robots in the industry, let’s answer basic questions such as what is a SCARA robot, how does it work and what are its advantages?

What is SCARA Robot?

SCARA is an abbreviation for Selective Compliance Assembly Robot Arm. SCARA robots stand out with their high speed, precision and repeatability.

SCARA robots, which have a special place among industrial robots, are used in many production processes such as assembly, transportation and quality control. Thanks to their compact structure and high cycle speeds, they offer effective solutions even in narrow spaces.

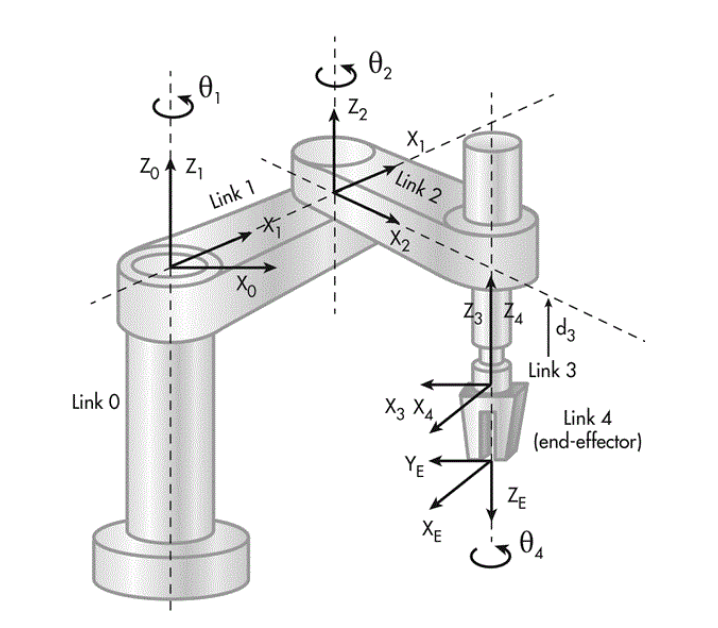

How Does SCARA Robot Work?

SCARA robots can be easily integrated into automation systems thanks to their unique programming capabilities. The software of the robots is sent to the control unit and they are made to perform operations in accordance with the specified program.

SCARA robots are integrated with air pressure vacuum grippers or gripper systems and have a wide range of use in different sectors. They provide effective results especially in applications requiring transportation, assembly and precision processing.

Advantages of SCARA Robots

The main reasons why SCARA robots are frequently preferred in the industry are:

- It provides fast integration thanks to its easy programmable structures.

- It accelerates production processes with its high cycle speed.

- It has a high sensitivity and accuracy rate, thus minimizing the margin of error.

- It has a long life thanks to its durable design that requires little maintenance.

- It does not need an external control unit, it can work independently.

- It reduces the need for operators, thus reducing labor costs.

These advantages make SCARA robots indispensable, especially for industries that require fast and precise processing.

Usage Areas of SCARA Robots

SCARA robots play a major role in production with their wide range of uses. Common areas of use are:

- Transport, Placement and Stacking Systems – Transport products to specific locations and stack them in an orderly manner.

- Measurement and Quality Control – Checks whether products meet size and quality standards.

- Packaging – Used in fast and error-free packaging processes.

- Assembly Applications – Provides assembly of components in the electronics, automotive and white goods sectors.

- Screwing Operations – Provides high accuracy in precision screwing and fixing operations.

- Image Processing Systems – Perform complex visual perception tasks by integrating with sensors and cameras.

- Life and Durability Tests – Used in long-term durability tests of products.

Thanks to these wide areas of use, SCARA robots have become one of the most important robot types that increase production efficiency in the industry.

Efficiency and Cost Advantages of SCARA Robots

One of the most important elements for manufacturers is efficiency and cost optimization. SCARA robots offer cost advantages in production processes thanks to their high speed, precision and low maintenance requirements.

One of the biggest reasons why SCARA robots are preferred is their low failure rates. Thanks to their long-lasting and durable structures, they prevent production lines from stopping and ensure continuity. This means time and cost savings for manufacturers.

SCARA Robot Manufacturers and IAI SCARA Robots

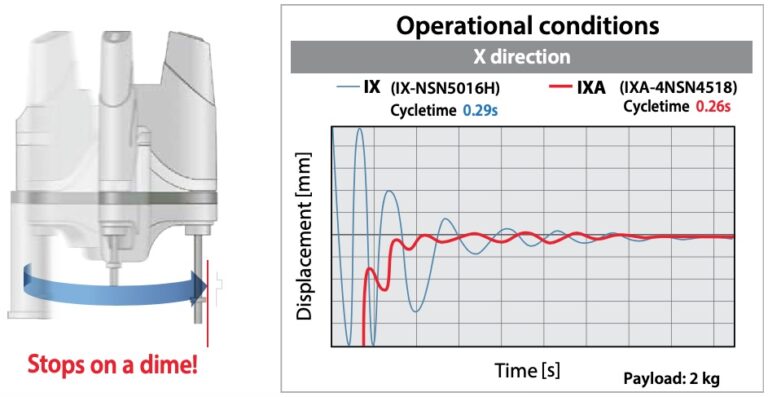

There are many different brands among SCARA robot manufacturers. However, one of the robots with the highest speeds and precision in the industry is IAI SCARA robots.

IAI is a pioneer in the sector by offering high speed, low vibration and precise positioning advantages with the SCARA robots it produces. Their long-lasting and durable structures put IAI robots one step ahead of their competitors.

The Future of SCARA Robots

With the developing technology, SCARA robots are becoming much more efficient by being integrated with artificial intelligence and image processing systems. Especially when combined with smart sensors such as Sensopart cameras, they provide a great advantage in complex assembly and transportation processes.

In the future of the industry, SCARA robots will reach higher speeds and precision levels and strengthen their place in production.

SCARA robots are one of the most preferred robots in terms of speed, precision and efficiency in industrial production. They offer great advantages especially in processes such as assembly, transportation, packaging and quality control. SCARA robots, which provide cost advantages to manufacturers with their low maintenance requirements and long-lasting structures, will continue to increase their importance in the industry with smarter and integrated systems in the future.

If you want to get more information about SCARA robots or determine the most suitable robot solution for your factory, you can contact our expert team!