Why Electric Actuators?

In industrial automation systems, efficiency and precision are at the forefront. Robot systems and actuators integrated into machines allow the process to be carried out in a more efficient and controlled manner. At this point, electric actuators stand out with their advantages such as versatile positioning, speed, precision and programmability. So, what is an electric actuator, what are its advantages and in what areas is it used?

What is an Electric Actuator?

Electric actuators are devices that convert electrical energy into mechanical motion. These systems, which usually provide linear or rotary motion, precisely convert incoming electrical energy into mechanical energy. They are widely preferred in industrial applications that require high precision.

Advantages of Electric Actuators

Electric actuators have a wide range of uses in the industry due to their features. Their prominent advantages can be listed as follows:

- Long-lasting: Thanks to their durable structures, they can be used for many years.

- Compact design: Provides easy integration into machines.

- Provides precise control: Can move with millimeter accuracy.

- Easy to program: Can be optimized for different applications.

- Easy to program: Can be optimized for different applications.

- Provides wide operating ranges: Can be used in different industrial areas.

- Works quietly: Moves without noise and vibration.

- Fast and efficient: Suitable for continuous and serial operation.

- Maintenance costs are low: Requires less maintenance than hydraulic and pneumatic systems.

Areas of Use of Electric Actuators

Electric actuators are used extensively in industrial automation systems in the following areas:

- In conveyor systems: Used in systems that separate and feed products on the belt.

- In test systems: Plays a role in sample placement and test equipment within the machine.

- In the health sector: Preferred in medical devices and laboratory automation.

- In the food industry: Used in packaging and processing machines.

- In the automotive industry: Common in robotic assembly lines and part placement systems.

- In machine manufacturing: Can be integrated into different machine systems.

- In the electrical-electronics sector: Used in systems that require precise positioning.

Thanks to these features, electric actuators have become an indispensable part of modern automation systems developed in accordance with the Industry 4.0 vision. Thanks to the convenience and diversity it offers to manufacturers, it offers a wide range of use in different sectors and optimizes production processes in many areas.

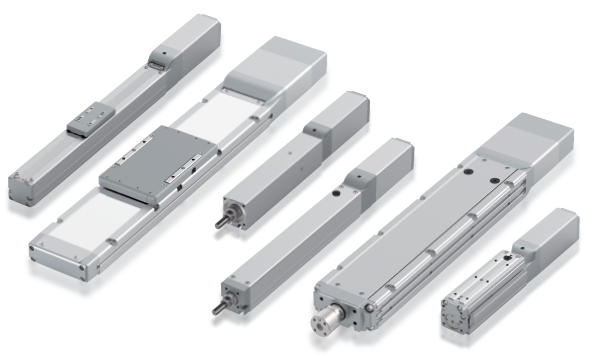

IAI Electric Actuators: Industry-Sought Performance

IAI, one of the leading companies in electric actuator technology, draws attention with its innovative actuator models. With its high speed, precision and accurate positioning features, IAI actuators are preferred by a wide audience in the industry.

You can make your systems more efficient by taking advantage of the advantages offered by electric actuators and achieve the best results in your automation projects.