Today, technological developments make it possible to carry out production processes faster and in higher quantities. However, this speed makes it difficult for operators to work without errors, especially in small parts assembly applications. Errors such as missing, incorrect or excessive parts can affect product quality and cause significant problems for businesses. At this point, the RICOH Assembly Assistant Camera comes into play as a solution.

What is the RICOH Mounting Assistant Camera and How Does It Work?

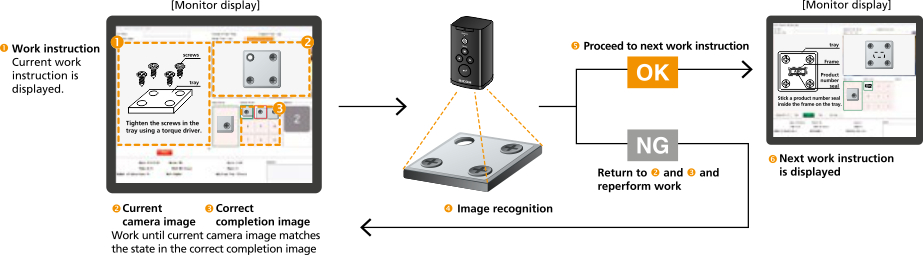

Using state-of-the-art image recognition techniques, RICOH compares each assembly step with predefined images, eliminating process errors caused by human error. The system does not allow a step to proceed unless it is completed correctly, thus minimizing assembly errors.

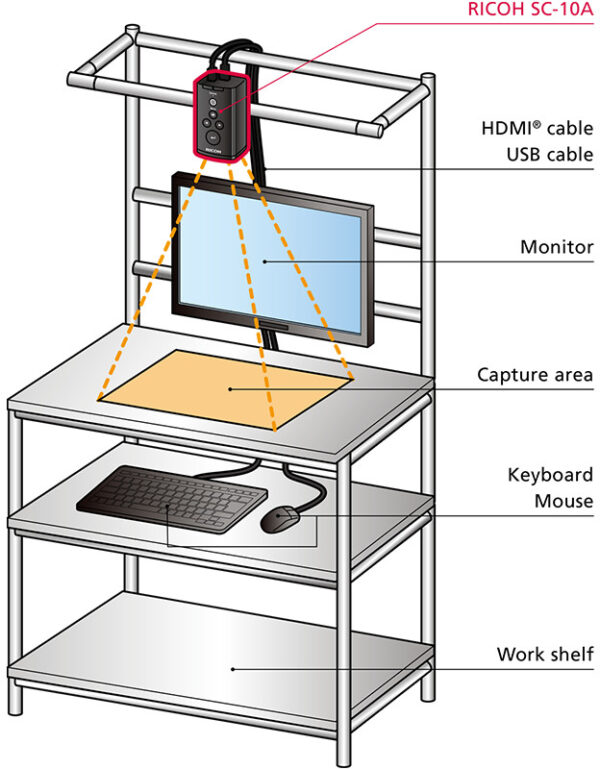

This solution is easy to set up, with no need for a controller or external resources. Thanks to RICOH’s integrated image recognition software, you can get started with just a mouse, keyboard and monitor.

Image recognition software is the ability of a computer-aided camera to identify and detect objects and features in a digital image or video. Image recognition technology works by detecting the salient regions that contain the most information about the image or object. It does this by isolating the most informative sections or features in a selected image and ignoring the rest of the features that are of little interest. The process uses an image recognition algorithm, also known as an image classifier, which takes an image as input and extracts the content of the image.

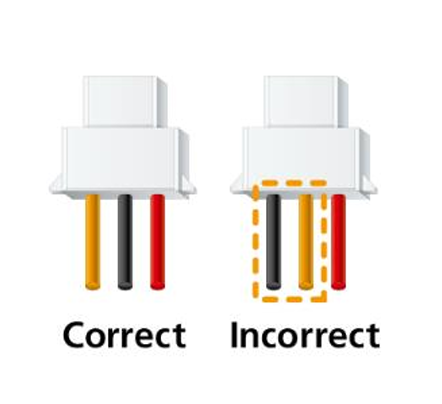

There are instructions prepared by the company on the screen so that the operator can follow the operations in order. The integrated image recognition system compares the actual work results of these work steps with the previously recorded correct versions and thus detects that the parts are missing or incorrectly assembled. In the event of an error during the operation, it acts as a corrective by preventing the next step until the error is corrected. It can also be used for training new personnel and standardizing the operation processes by preventing work errors.

Areas of Use

RICOH can be used in many different applications:

- Checking for missing or incorrect parts during assembly,

- Product placement and removal processes in the box,

- Accuracy of packaging procedures in transportation operations,

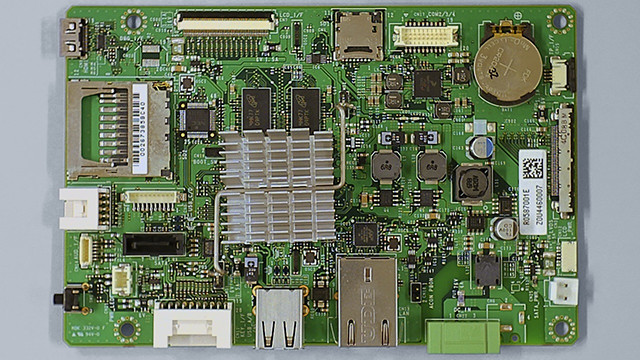

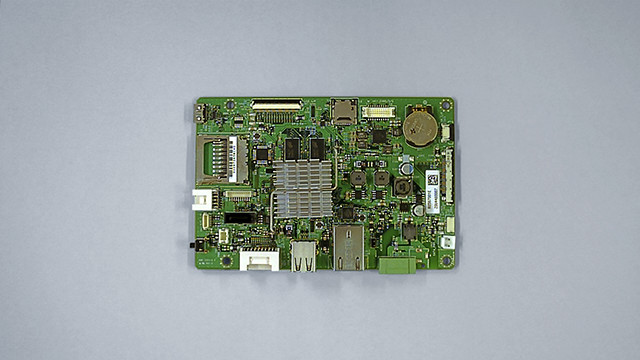

- Component placement checks on the electronic card.

Advantages

The RICOH Mounting Assistant Camera offers businesses the following benefits:

- Increased Work Efficiency: The system eliminates the need for re-checking by preventing assembly errors.

- Easy Traceability: Operator performance and process data are recorded, making quality management more efficient.

- Environmentally Friendly Solutions: No need for paper instructions and reduced manual control processes.

- Standardized Operation: Operations are carried out according to certain standards, eliminating individual differences.

Technical Specifications

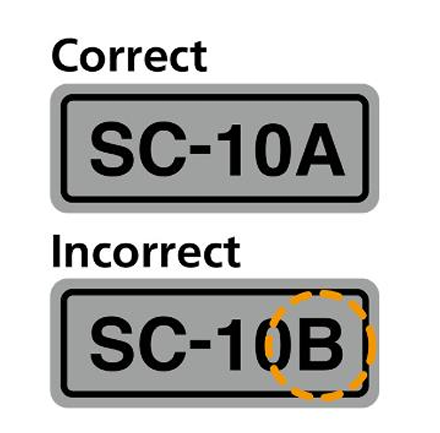

RICOH’s mounting distance varies between 400-800mm. For smaller products, the SC-10A(H) model with high magnification ratio can be used. In addition, instructions prepared in Microsoft Office can be easily optimized and integrated into the system.

High magnification model: RICOH SC-10A(H)

Standard model: RICOH SC-10A(H)

Sample Applications

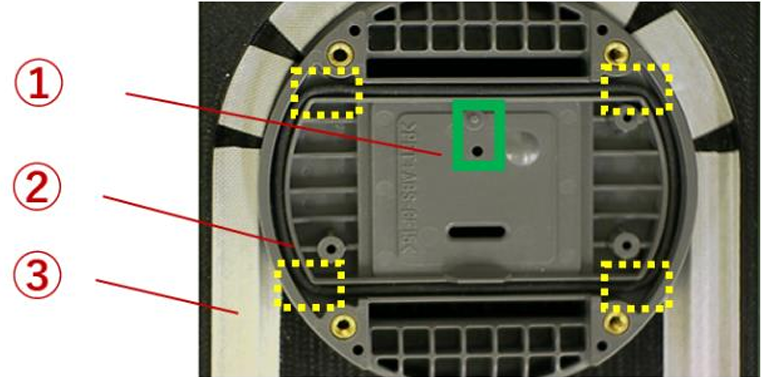

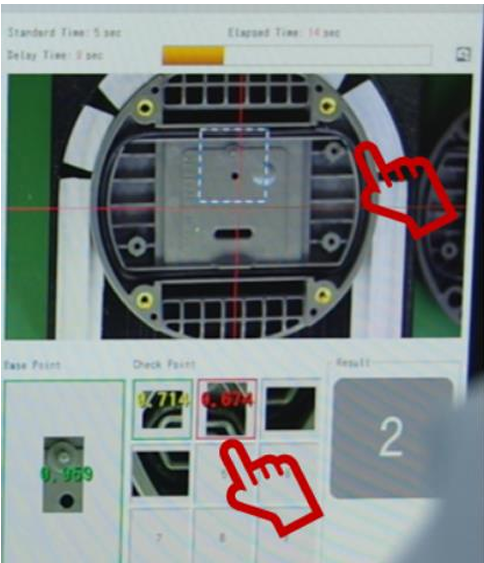

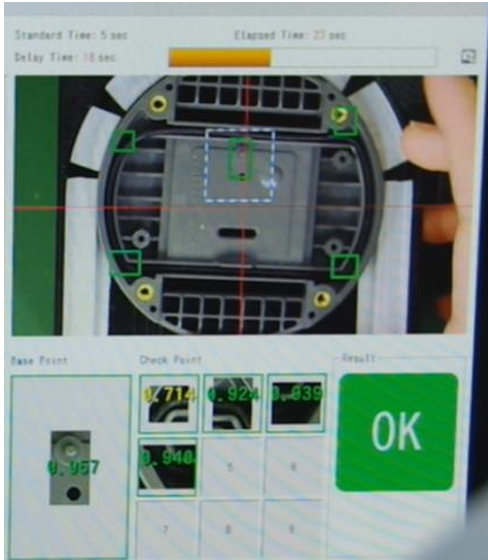

O-ring control

In the example application, the operator has performed the first stage while checking the o-ring. The camera does not allow the other stages to proceed without correctly performing the second stage assembly. If the desired stages are performed, the camera receives an OK response.

Preventing incorrect part placement

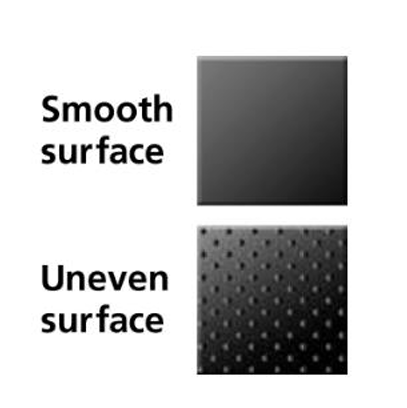

Assembly control by texture

Separation of similar products by taking the reference part

Assembly control by color

The RICOH Assembly Assistant Camera not only reduces the error rate in assembly processes, but also makes production processes more efficient and traceable. For more information, visit our website and view application examples.