![]()

The challenge:

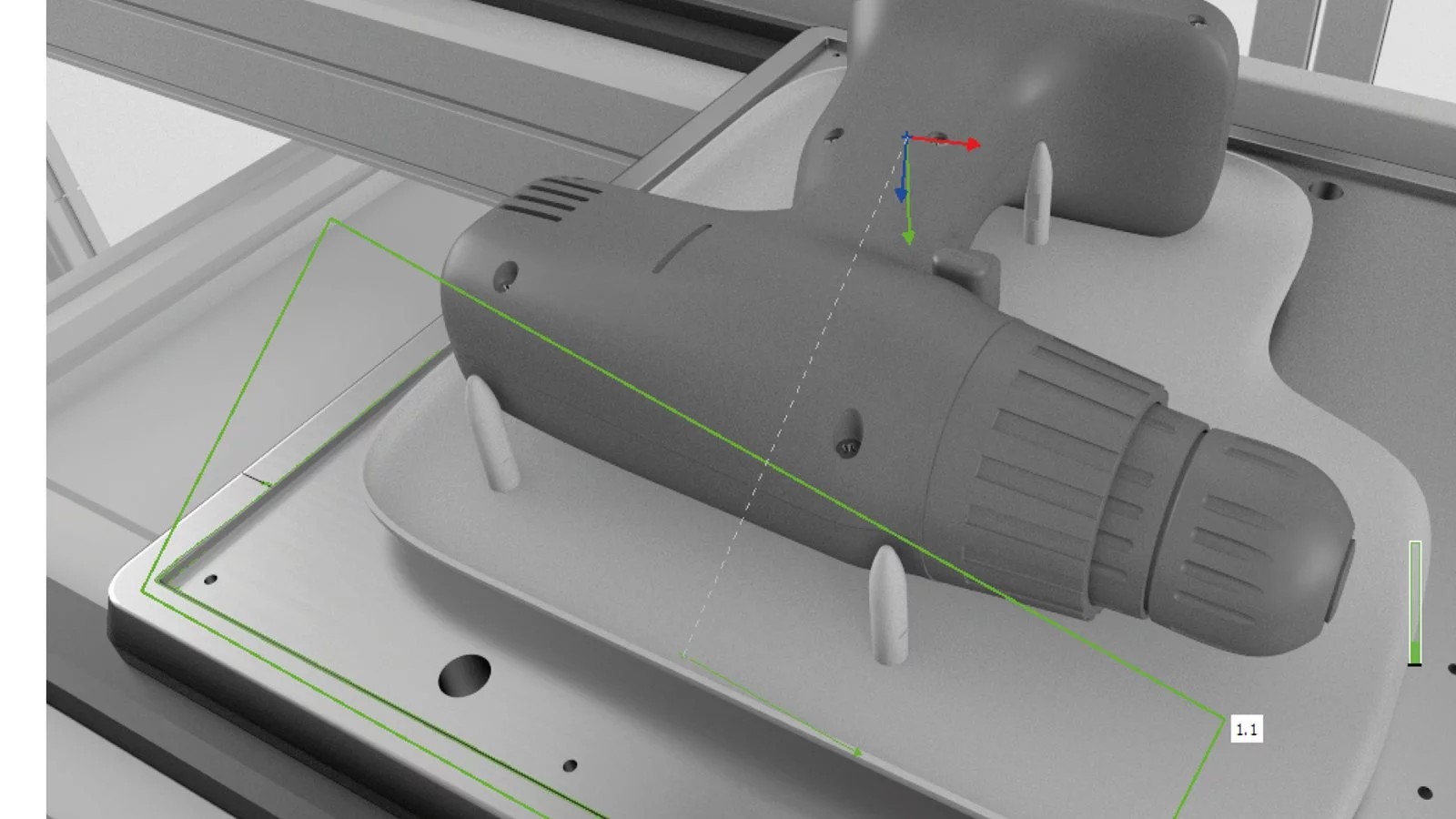

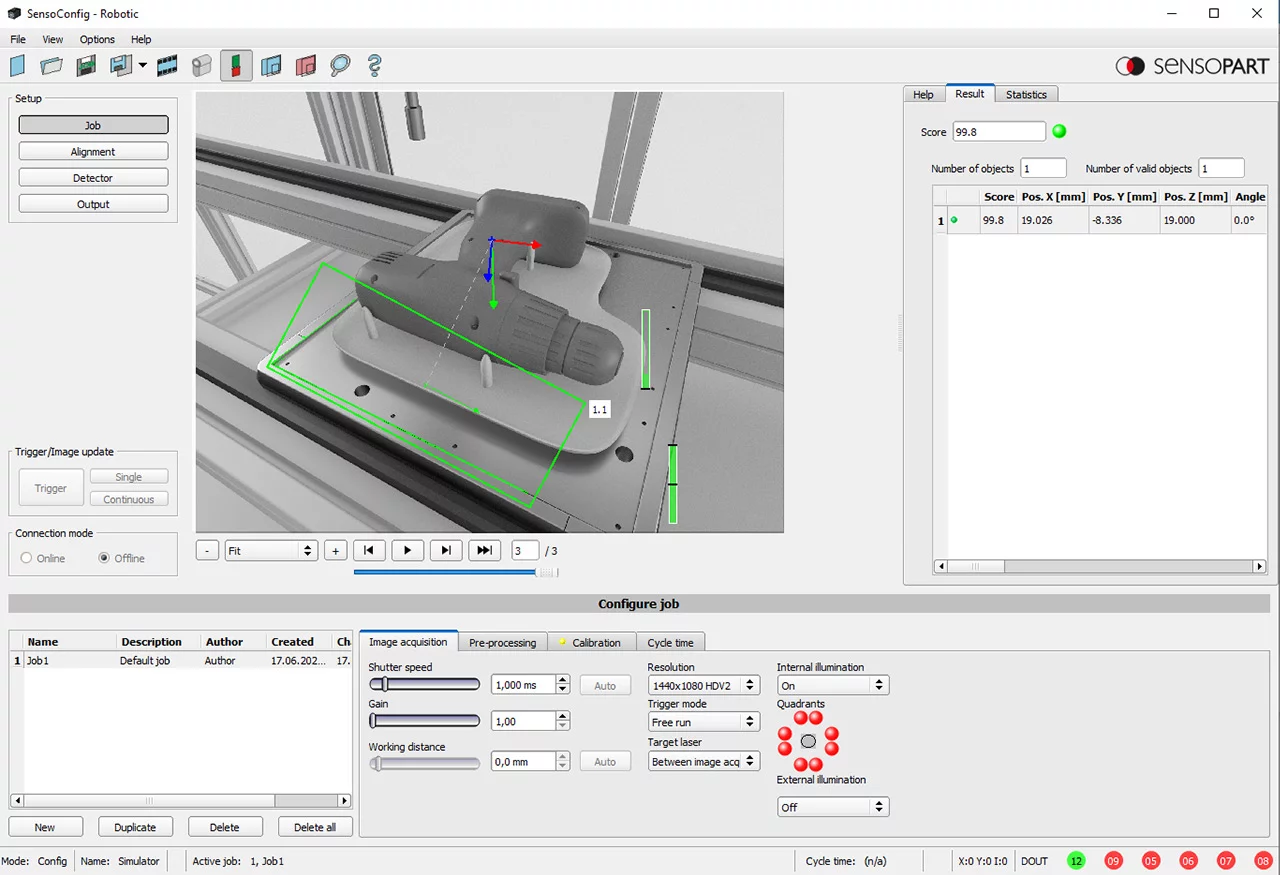

When screwing the outer casing of the cordless screwdriver together, several parameters must be observed – from the order of the screws to the different tightening torque for the individual screws. The varied positions at which the parts are fed complicates the process step even further.

Our solution:

For a reliable detection of the component position, the VISOR® Robotic vision sensor is mounted on a stationary arm, where it determines the location and orientation of each of the case halves and adjusts the screw insertion points accordingly.

Your benefits:

- Reduced programming due to the automatic calculation by VISOR® Robotic of robot’s 3D start position

- Increased throughput, uptime and overall quality

- Reduced mechanical complexity, therefore allowing flexible expansion of installation