The RICOH SC-20 is a work inspection camera that detects mistakes during the assembly process. It can conduct real-time quality checks during a job, something exterior inspection cameras are not capable of. It can perform automatic checks of assembly status such as similar parts, missing parts, and work order, and perform batch inspections after a job is completed. Because the system is easy to set up without the need for a computer, it is easy to begin digital inspections.

RICOH SC-20 Process and Final Control System

It automatically controls the workflow using Image Processing Technology and provides efficiency in business management.

The RICOH SC-20 is a work inspection camera that detects mistakes during the assembly process. It can conduct real-time quality checks during a job, something exterior inspection cameras are not capable of. It can perform automatic checks of assembly status such as similar parts, missing parts, and work order, and perform batch inspections after a job is completed. Because the system is easy to set up without the need for a computer, it is easy to begin digital inspections.

Real-time inspections during a job

Image recognition and instruction steps are linked. You can import work instructions and display them on the screen to automatically check work procedures, such as whether screws have been tightened in the right order. If the work does not go according to the instructions, the system prevents the worker from proceeding, helping eliminate mistakes and improve quality. The system supports accurate acquisition of work procedures in a short period of time.

High-precision judgments

This camera is equipped with a 1/1.8 inch, 8 megapixel CMOS color sensor. It enables high-precision inspections using digital images (4K/QFHD) with 9 times higher resolution than conventional models. It also uses an interchangeable C mount lens, so you can select from 5 high-resolution, RICOH FA lens (machine vision lens) focal lengths that offer minimal distortion to the edge of the image to match the size of your workpiece.

Easy connection to external devices

Use the HDMI, USB (Type-A/C), general-purpose I/O port, LAN port, wireless LAN* or Bluetooth®* to connect to external devices. You can streamline the inspection process if you connect a touch panel monitor, wireless mouse, PLC, controller, LED indicator lamp, buzzer, sensors, foot switch, electric screwdriver, etc.

* Wireless LAN and Bluetooth are supported only on the models with a wireless communication system.

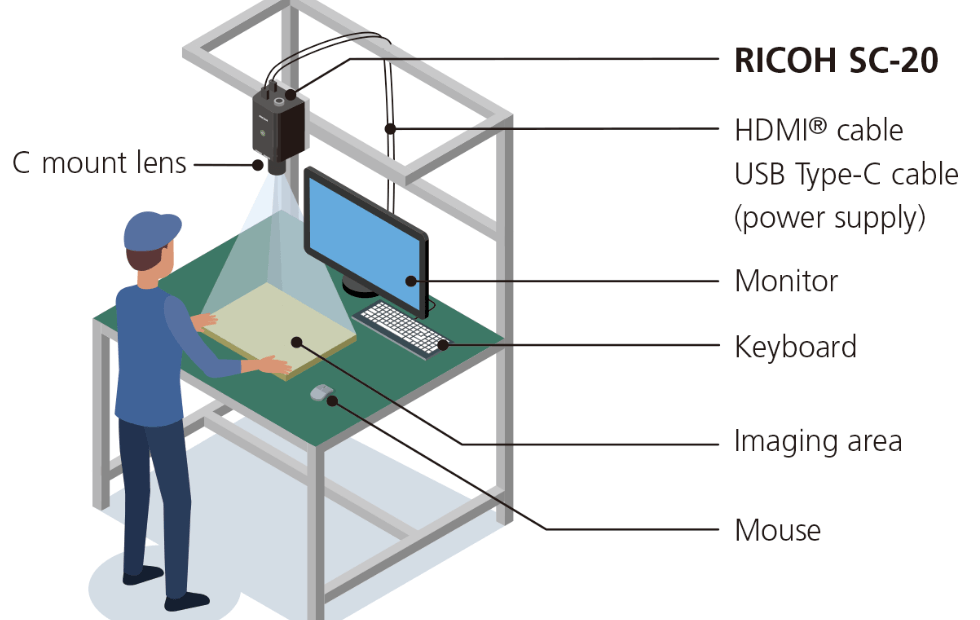

System Configuration

All you need is a mouse, a keyboard and a standard monitor.

Since there is no need for a PC, the cabling, space requirement and cost are reduced.er.

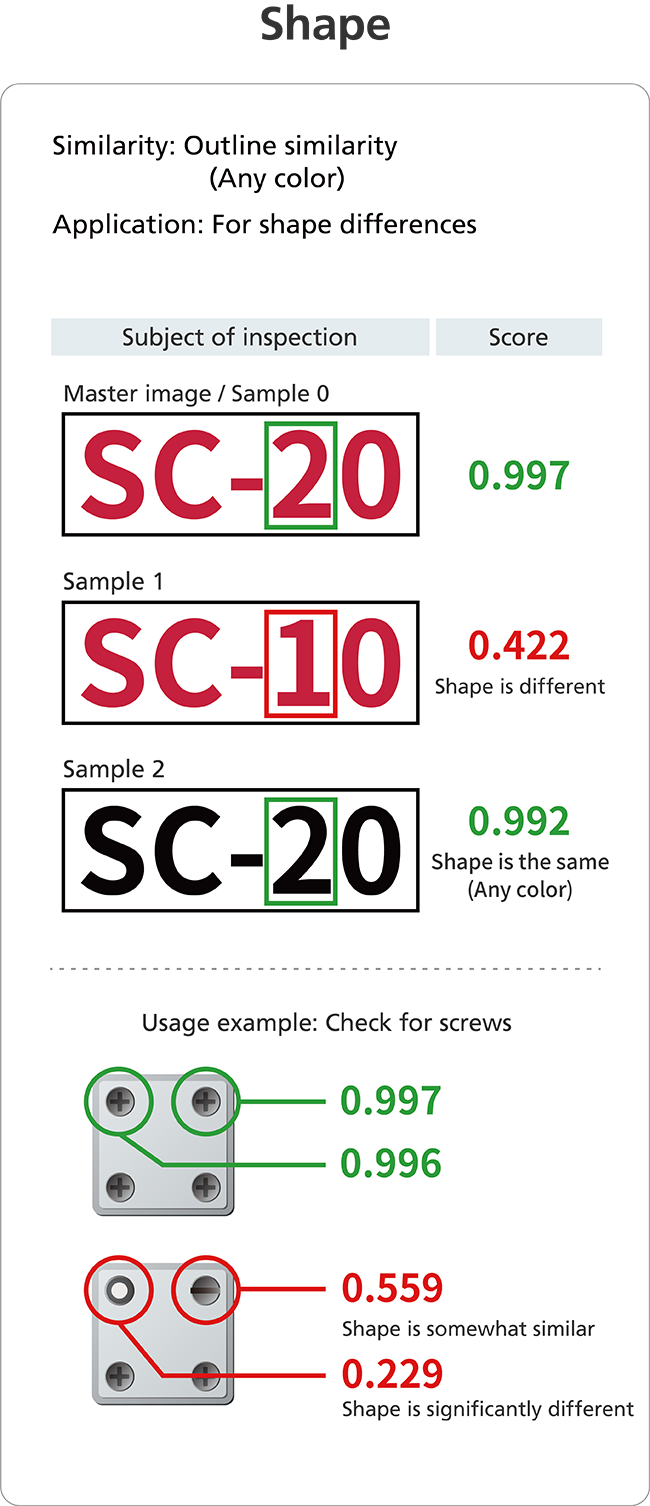

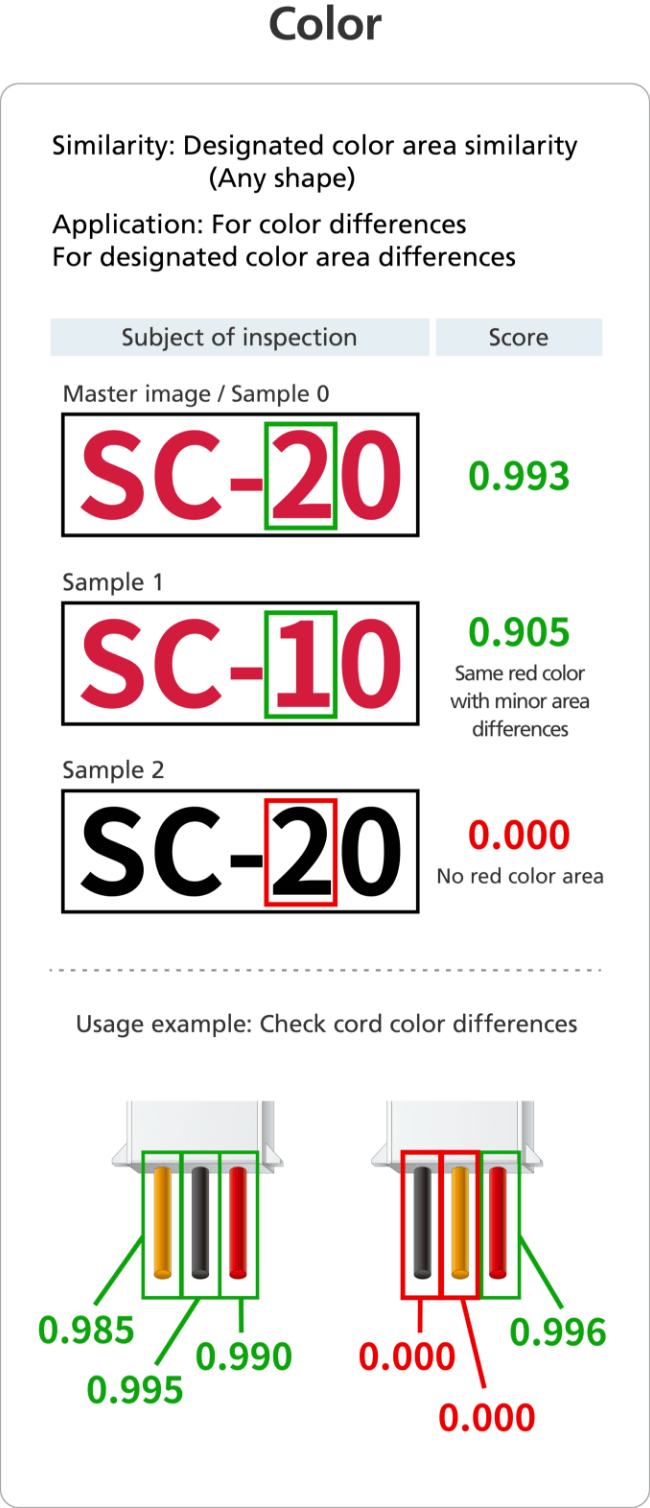

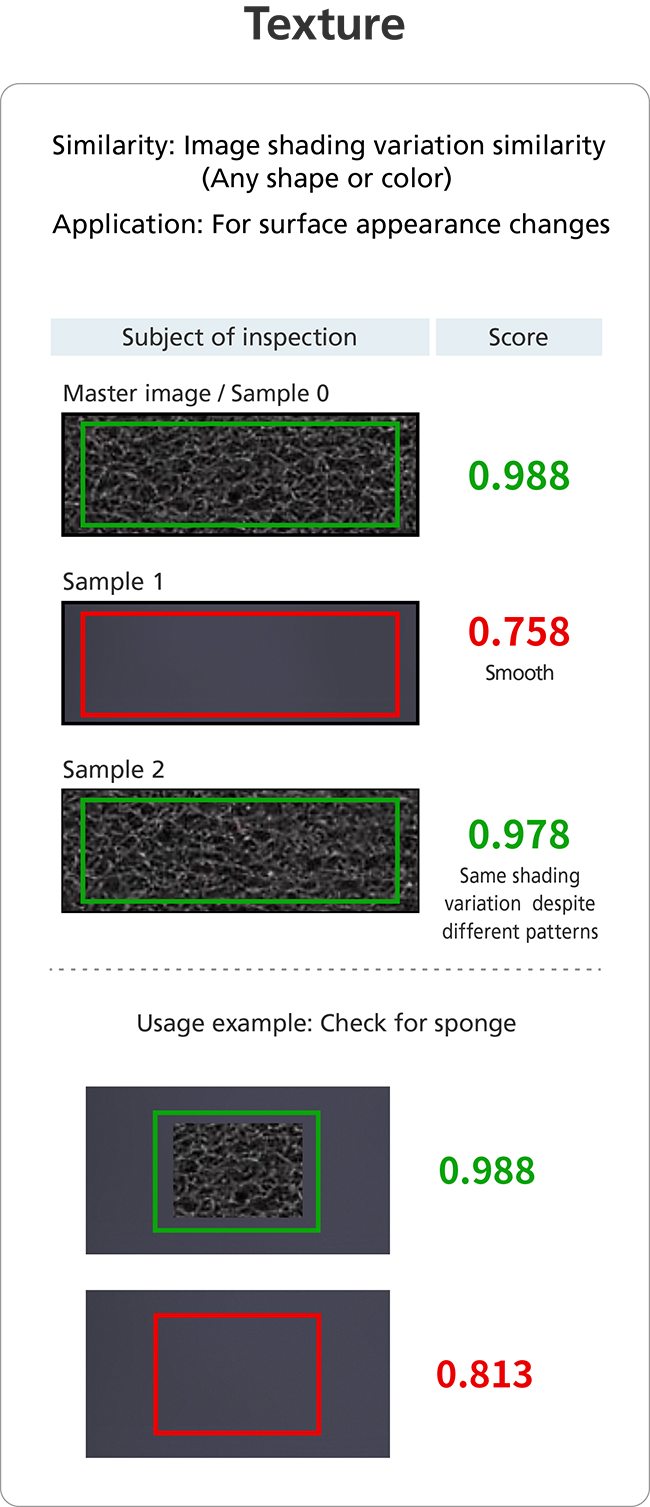

Similarity score judgment logic for matching judgment (reference information)

Placing / Receiving From Parcel

It can be checked that there are enough parts for assembly.

It can be checked whether the correct types of parts are placed in the parcel.

Assembly operation

The work order is displayed step by step to the operator on the monitor.

It is checked whether the work steps are working as planned.

Lack of a part that cannot be seen later during assembly can be prevented during assembly.

Quality Control Operation

It can be checked whether there is any error in the assembled part.

Human error is eliminated without the use of additional labor

Transport Operation

Compliance of all products and packaging type in the package with the procedures can be controlled.

You can visit the RICOH website for more information.

You can contact us via our contact information to get detailed information about Work Assistant Camera Systems.

How to set up a work inspection?

The inspection process