With model matching, the RICOH SC-10A automatically checks for similar part, wrong part, work instruction and other assembly conditions during the work process. Many information such as serial number, assembly operator, working time, work result images can be recorded in the database and used for job analysis and traceability.

RICOH SC-10A Process and Final Control System

One All-in-One Unit

With model matching, the RICOH SC-10A automatically checks for similar part, wrong part, work instruction and other assembly conditions during the work process. Many information such as serial number, assembly operator, working time, work result images can be recorded in the database and used for job analysis and traceability.

Operator errors are prevented with Image Recognition Technology.

In the event of an error during operation, it acts as a corrector, preventing going to the next step until the error is corrected.

Very easy to use with the All-in-One system

Since the camera, Image Processing and software are in an integrated body, it is very easy to install and use. It does not require an extra control unit, PC, etc. hardware.

Work orders can be transferred to the system very easily.

Computerizes your business

During the operation, all inputs and outputs are recorded and job analysis can be done and traceability is provided.

It eliminates the use of paper thanks to digital work orders and control forms.

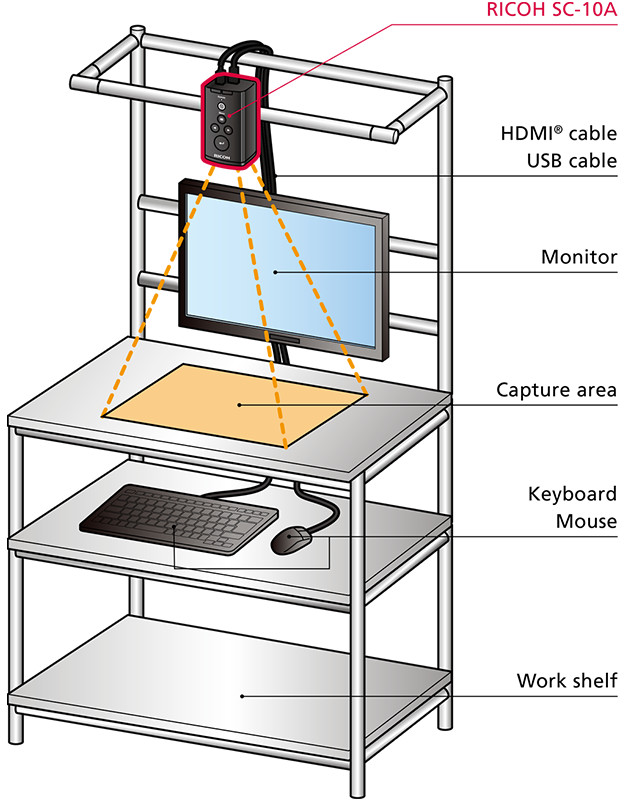

System Configuration

All you need is a mouse, a keyboard and a standard monitor.

Since there is no need for a PC, the cabling, space requirement and cost are reduced.

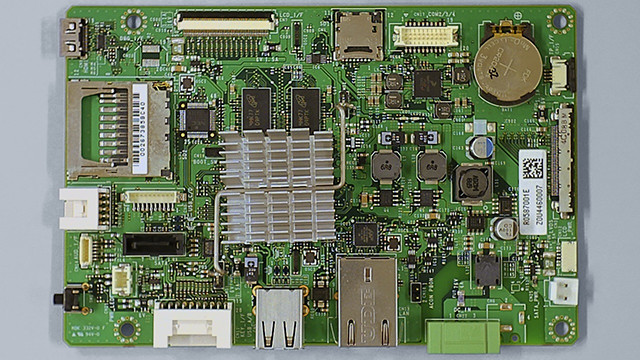

High magnification RICOH SC-10A (H)

The SC-10A (H) model, which emerged with the addition of a high magnification lens, allows working on small products even when the camera cannot be mounted close to it.

For example, the placement of components on an electronic board, even correct / faulty controls can be checked.

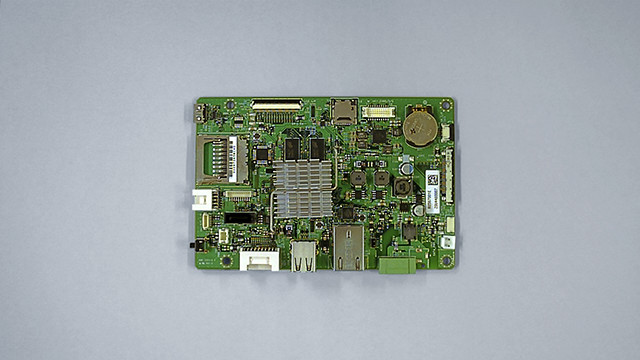

High magnification and Standard model comparison

High magnification model: RICOH SC-10A (H)

Standard model: RICOH SC-10A (H)

Placing / Receiving From Parcel

It can be checked that there are enough parts for assembly.

It can be checked whether the correct types of parts are placed in the parcel.

Assembly operation

The work order is displayed step by step to the operator on the monitor.

It is checked whether the work steps are working as planned.

Lack of a part that cannot be seen later during assembly can be prevented during assembly.

Quality Control Operation

It can be checked whether there is any error in the assembled part.

Human error is eliminated without the use of additional labor

Transport Operation

Compliance of all products and packaging type in the package with the procedures can be controlled.

Panel PC Assembly

Wearable Sensor Mount

Product Grouping Process