| Shape | Type | Width | Stroke | Ball Screw Lead (mm) | Maximum Speed (mm/s | Maximum Payload (kg) |

Maximum Acceleration |

|

| Horizonta | Vertical | |||||||

| Piston | RA5C | 52mm | 50mm – 400mm |

20 | 800 | 6 | 1.5 | 1G |

| 12 | 700 | 25 | 4 | |||||

| 6 | 450 | 40 | 10 | |||||

| 3 | 225 | 60 | 20 | |||||

| RA6C | 61mm | 50mm – 500mm |

24 | 800 | 20 | 3 | 1G | |

| 16 | 700 | 50 | 8 | |||||

| 8 | 420 | 60 | 18 | |||||

| 4 | 210 | 80 | 28 | |||||

| 1.5 Times Higher Maximum Speed, 2 Times The Payload | |

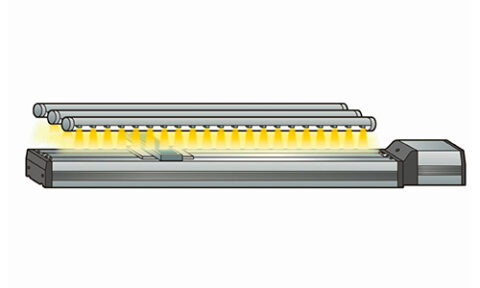

| When the new controller (Power CON 150) equipped with newly developed high-output driver is used, the maximum speed increases significantly by up to 1.5 times the levels achievable with conventional models, while the payload is greater by up to twice. In addition, the maximum speed does not drop as much even when the payload increases.

Due to increased torque with the high speed motor, meaning that dynamic performance equivalent to that of a higher-class model can be achieved at lower cost. |

|

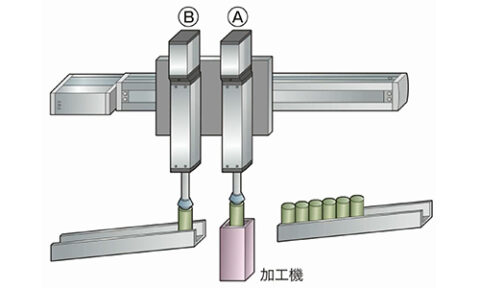

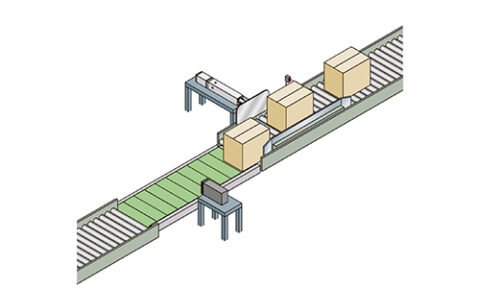

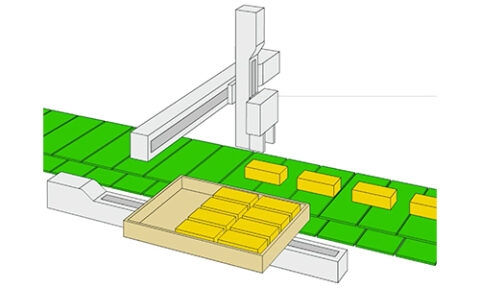

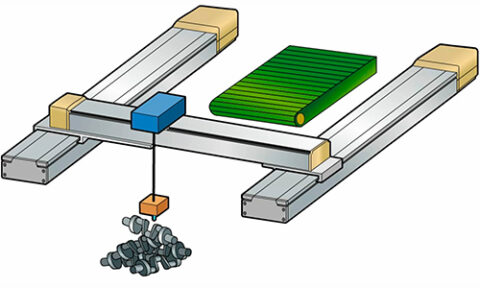

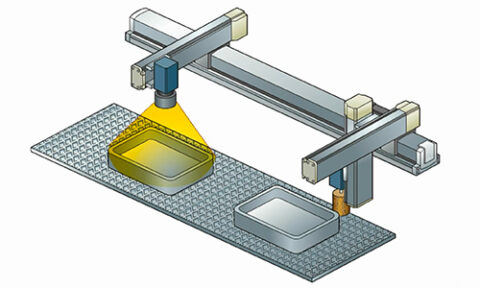

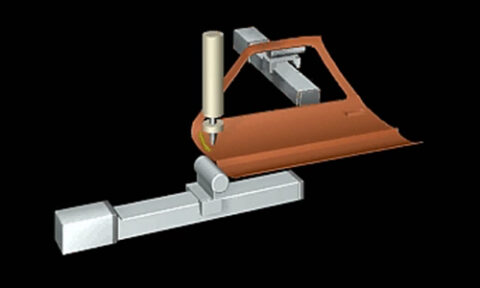

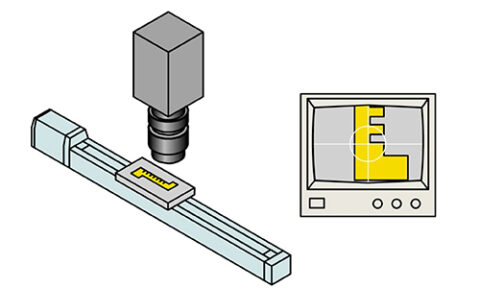

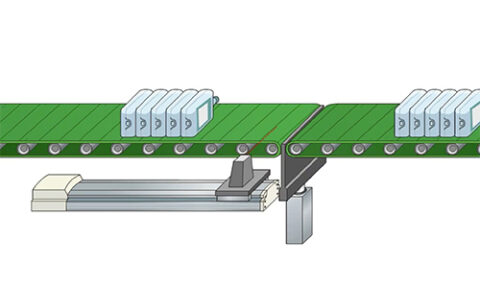

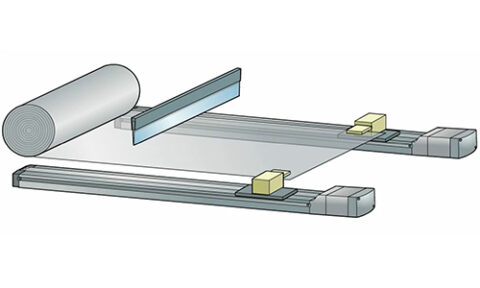

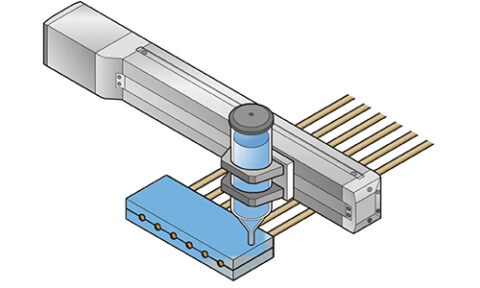

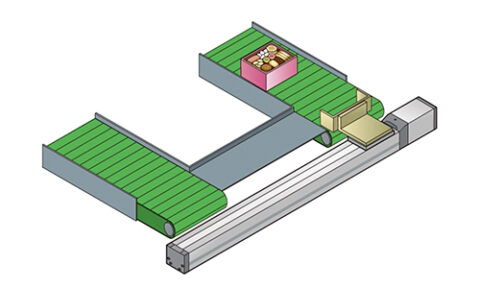

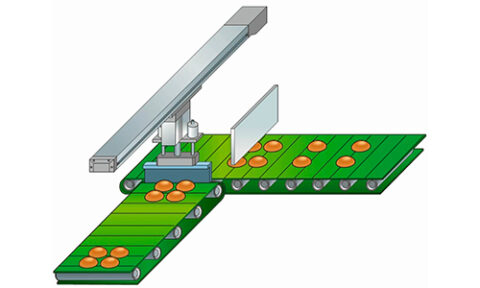

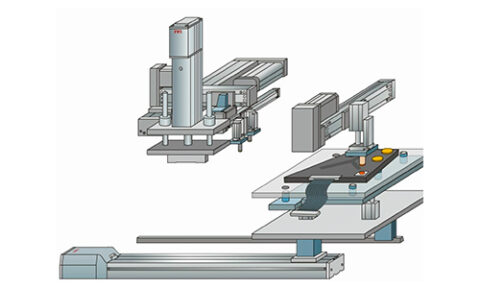

| Wide Variety of Models | |

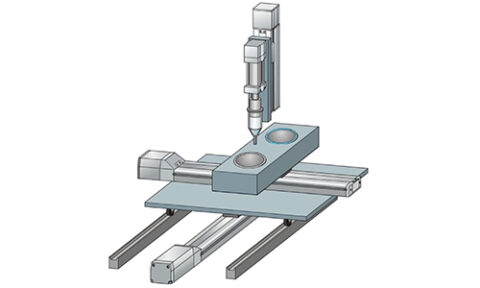

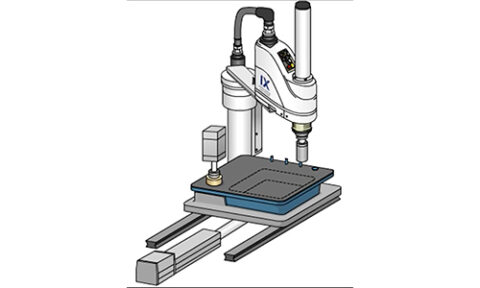

|

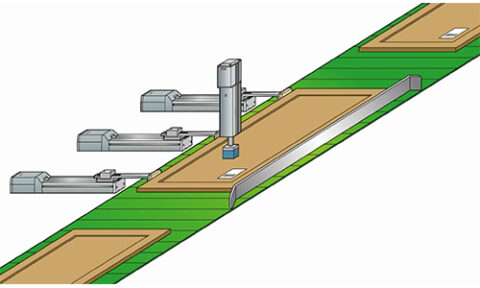

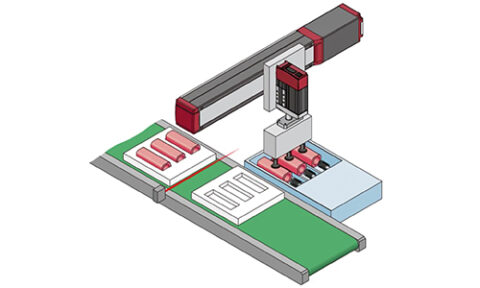

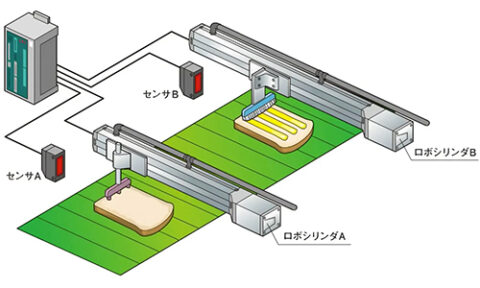

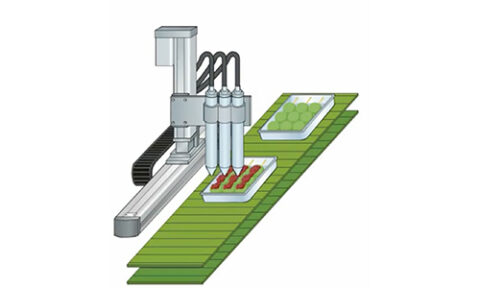

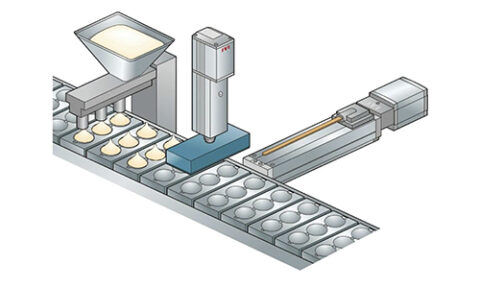

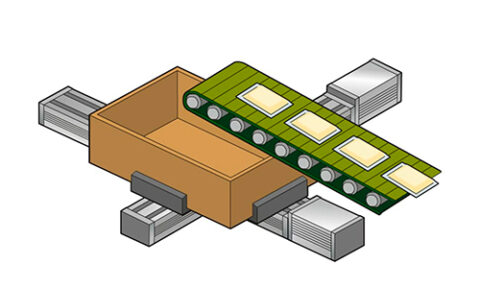

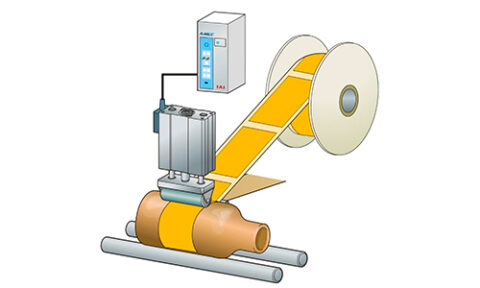

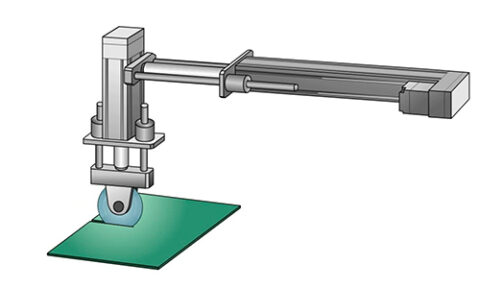

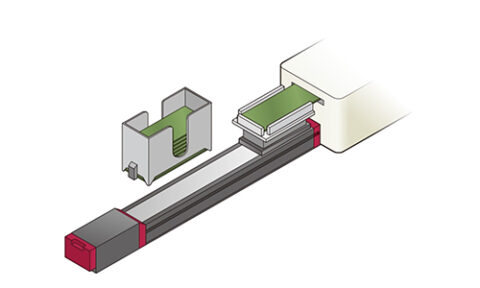

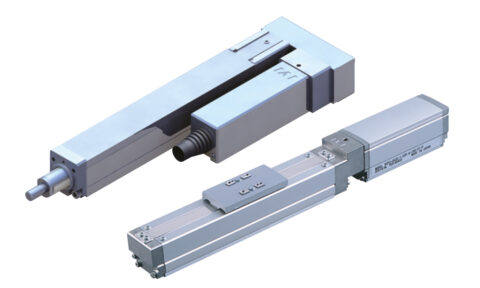

With 3 slider type and 2 piston type actuators, a wide range of models are available with options for each model.  |

|

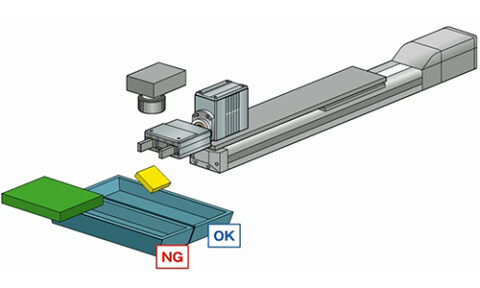

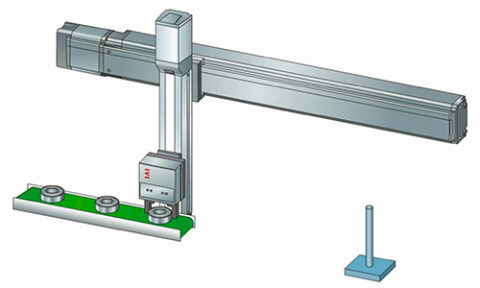

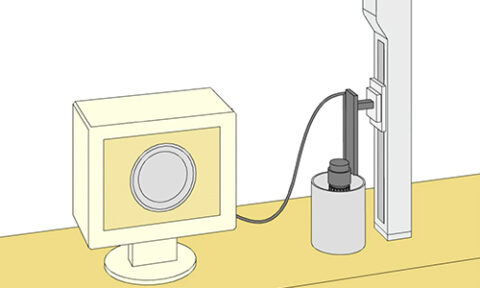

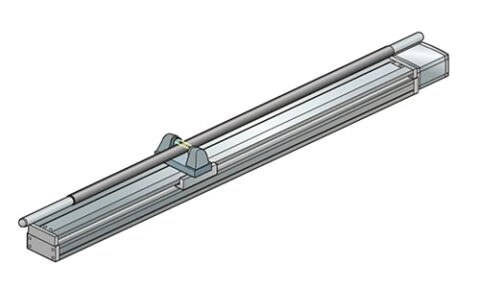

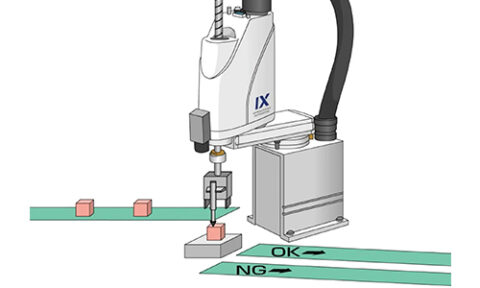

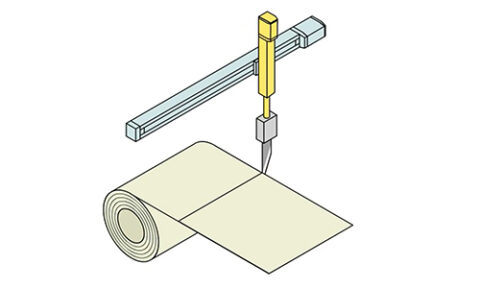

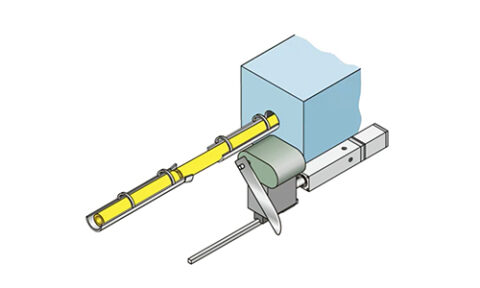

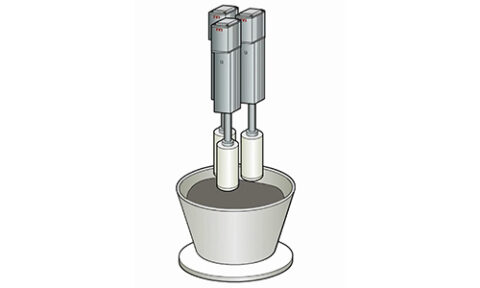

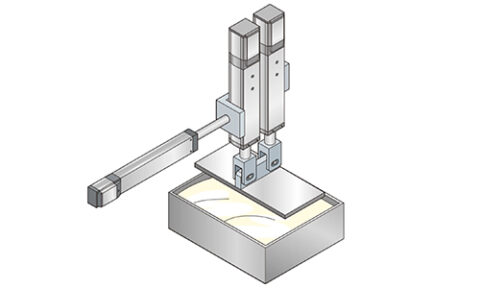

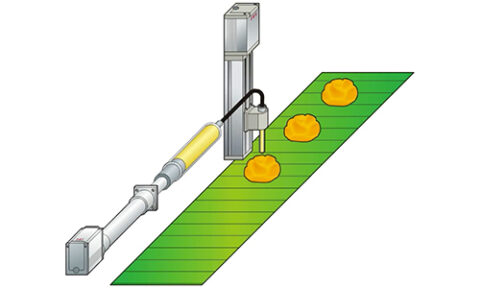

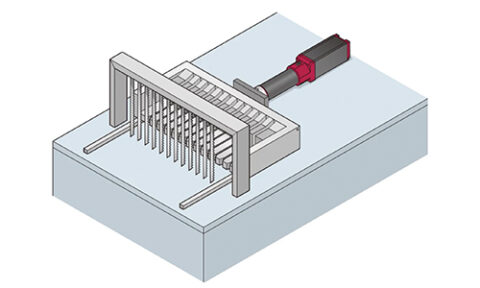

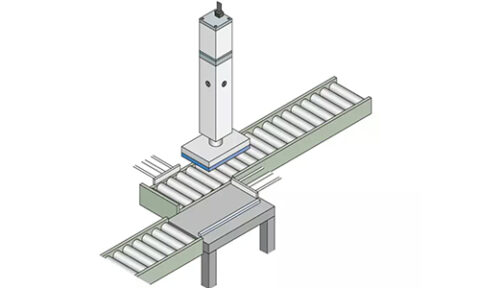

| Pistons with Higher Radial Strength Thanks to Built-In Guide Mechanism | |

| The rod type has a built-in guide mechanism in the actuator to carry radial loads on the rod over a long stroke of up to 500 mm.

|

|

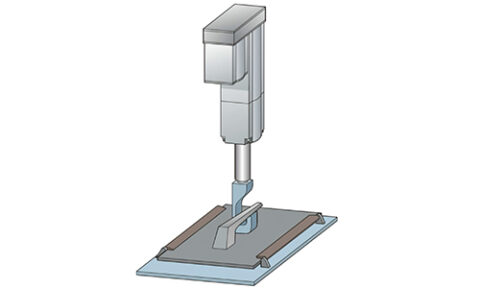

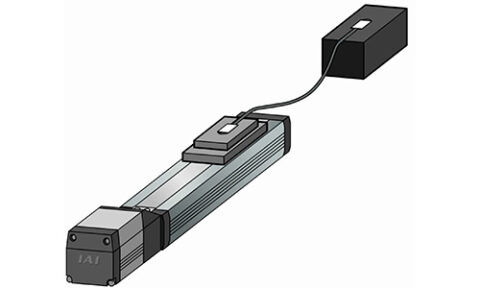

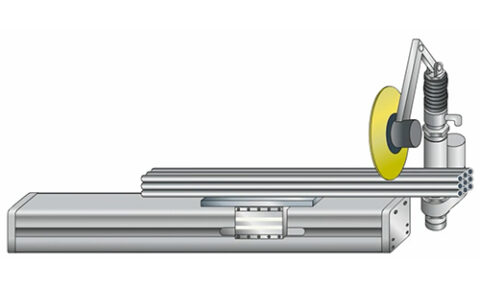

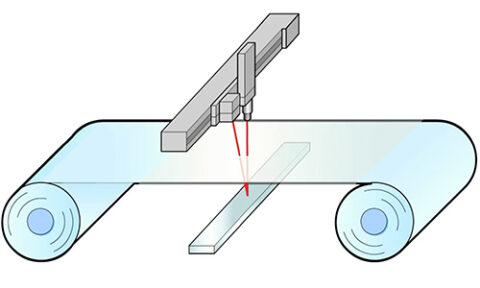

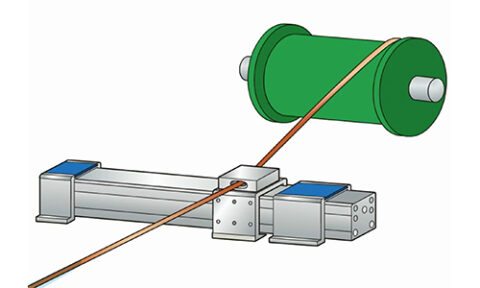

| Easy Motor Replacement | |

|

The actuator and motor unit can be separated and replaced by removing only one setscrew, so the time required for maintenance becomes significantly shorter.  |

|

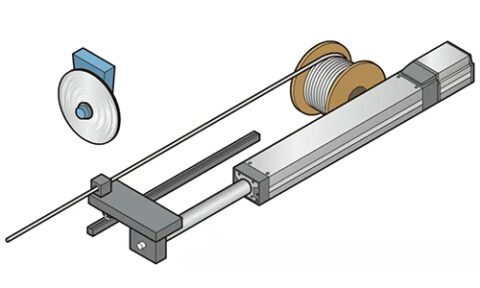

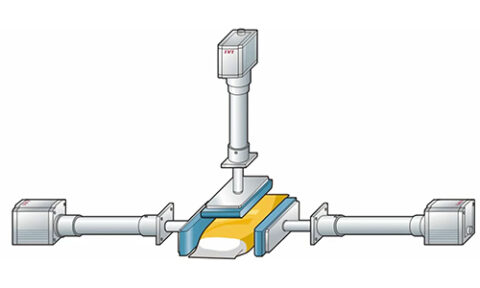

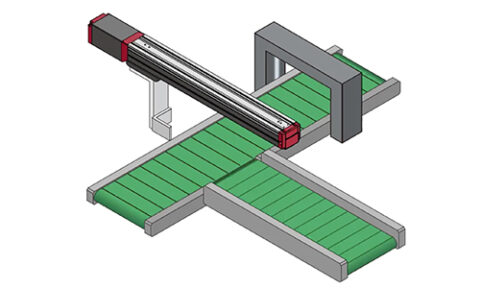

| Mounting Holes Compatible with RCP2 Series | |

|

Slider types have mounting holes that are compatible with RCP2 actuators, meaning that you can replace your current RCP2 actuator with a RCP4 with ease Also, the mounting holes provided on rod types are the same as those provided on slider types and reamed holes are also provided to significantly improve installation repeatability.  |

|

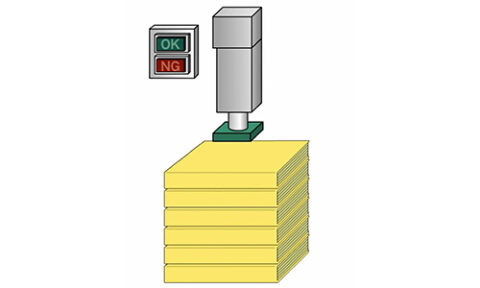

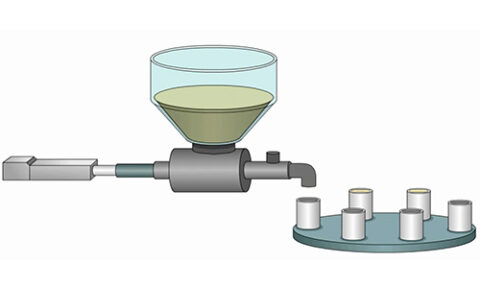

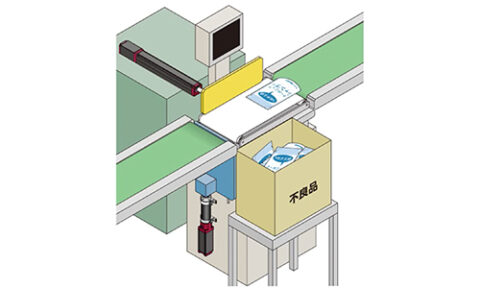

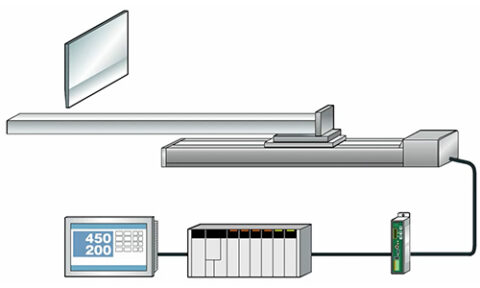

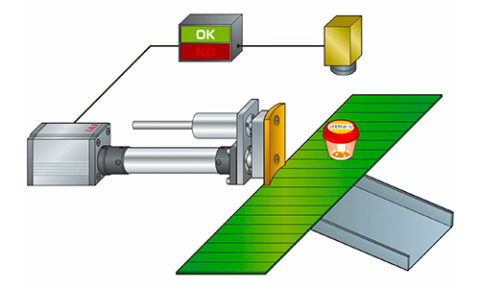

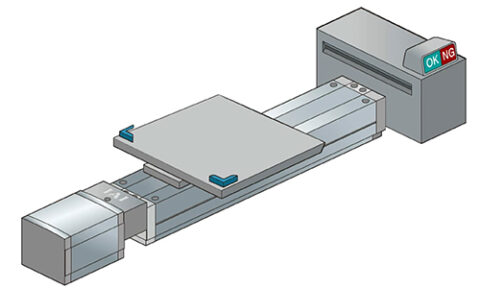

| Total Movement Counter Function | |

| The total number of times the actuator has moved is counted and recorded in the controller, and a signal is output to an external device once the pre-defined count is exceeded. |  |

| Maintenance Notification | |

| Thanks to counter function, a signal is output to an external device once the pre-defined count is exceeded so that you know when to add grease or perform periodic maintenance. | |

| The Calendar Function | |

|

The calendar function (clock function) lets you add timestamps to the history of alarms, etc. This information is useful in troubleshooting, etc.  |

|

| The Smart Tuning Function | |

|

By entering a desired speed in the position data table, the maximum settable acceleration/deceleration will be set automatically according to the pre-defined load-speed combinations.  |

|

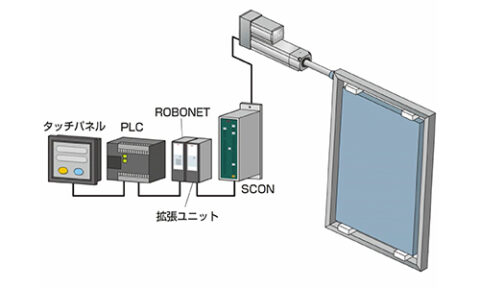

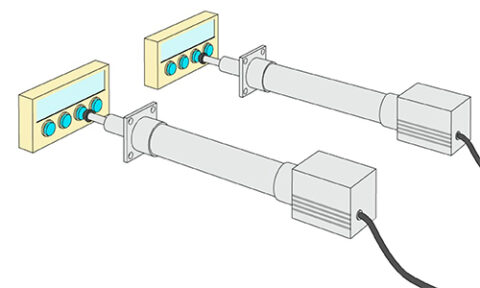

| PIO/Pulse-Train Controller Operation Types | |

| PCON-CA control unit can be used in positioning mode as well as in pulse train mode for direct positioning. It does not require any extra device. | |

| Motor Silencer Function | |

| Typical operating noises of pulse motors are reduced at low speed. | |