It offers high-performance part feeding, pre-orientation, optimum surface distribution of cast parts and components.

ASYRIL

3-Axis Vibration Robotic Parts Feeder

Asyril’s award-winning Asycube flexible feeders offer:

- High-performance part feeding

- Pre-orientation

- Optimal surface distribution of bulk parts and components

Asycube Advantages

- Compatible with all part geometries: 99 % of parts can be fed — including complex geometries and delicate materials.

- Minimum change-over times allow flexible, future-proof production systems.

- Extremely gentle part handling thanks to 3-axis vibration; parts move in all directions with the right flipping amplitude. Platform purge possible.

- State-of-the-art voice-coil actuators increase reliability and durability — no compressed air required.

- Precise part detection via integrated adjustable back-light or optional EYE+ / SmartSight.

- Easy configuration with Asyril Feeder Control Center software.

- Simple system integration through plug-ins for all major robot brands.

- Standard communication protocols (TCP-IP, Modbus) for straightforward automation integration.

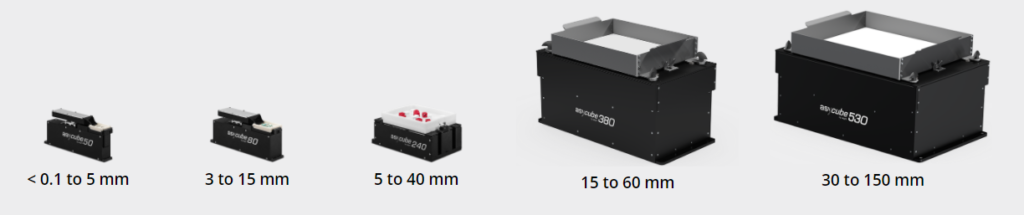

Asycube Product Range

Asycube 50

Ideal flexible feeder for parts 0.1 – 5 mm (flat/cubic) and up to 10 mm (long parts such as pins and needles).

Dimensions

- Vibratory platform: 45 × 34 mm (≈ 50 mm diagonal) / 1.3 × 1.8 in (≈ 2 in diagonal)

- Feeder (L × W × H): 293 × 46 × 138 mm / 11.5 × 1.8 × 5.4 in

- Hopper: 10 cm³ or 110 cm³

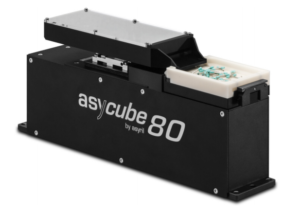

Asycube 80

Ideal flexible feeder for parts 3 – 10 mm (flat/cubic) and up to 15 mm (long parts).

Dimensions

- Vibratory platform: 65 × 52 mm (≈ 80 mm diagonal) / 2.6 × 2.1 in (≈ 3.1 in diagonal)

- Feeder (L × W × H): 320 × 61 × 138 mm / 12.6 × 2.4 × 5.4 in

- Hopper: 160 cm³

Asycube 240

Ideal flexible feeder for parts 5 – 40 mm (flat/cubic) and up to 50 mm (long parts).

Dimensions

- Vibratory platform: 195 × 150 mm (≈ 240 mm diagonal) / 7.6 × 5.9 in (≈ 10 in diagonal)

- Feeder (L × W × H): 300 × 171 × 132 mm / 11.8 × 6.7 × 5.2 in

- Hopper: 2 L or 3 L

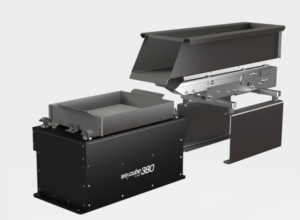

Asycube 380

Ideal flexible feeder for parts 15 – 60 mm.

Dimensions

- Vibratory platform: 254 × 325 mm (≈ 380 mm diagonal) / 10 × 12.8 in (≈ 14.96 in)

- Feeder (L × W × H): 499 × 257 × 307 mm / 19.6 × 10.1 × 12.1 in

- Hopper: 10 L

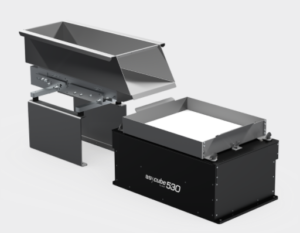

Asycube 530

Ideal flexible feeder for parts 30 – 150 mm.

Dimensions

- Vibratory platform: 427 × 371 mm (≈ 530 mm diagonal) / 16.8 × 14.6 in (≈ 20.9 in)

- Feeder (L × W × H): 600 × 372 × 320 mm / 23.7 × 14.7 × 12.6 in

- Hopper: 15 L

Asycube Clean 230

Flexible feeder for hygienic applications

Dimensions

- Vibratory platform: 230 mm (diagonal)

- Overall size (W × L): 177.5 × 237.5 mm

- Suitable part sizes: 5 – 40 mm

Features

Designed specifically for cleanroom and pharmaceutical environments, the Asycube Clean 230 is the first flexible feeder engineered to meet the strictest GMP Annex 1 requirements. Compact enough to fit into a 190 Rapid Transfer Port (RTP), its sterilizable plate and chemical-resistant design enable seamless integration into robotized isolators and aseptic zones.

Unlike traditional bowl feeders, the Asycube Clean 230 offers unmatched flexibility: no custom tooling, faster changeovers, and full adaptability for small batches and personalized healthcare.

The Asycube Clean 230, like our other products, also features Asyril’s patented 3-axis vibration technology and works seamlessly with the Eye+ Smart Control System, ensuring fast and accurate part detection.

Built for robots, ready for the future! It’s the smarter, safer choice for modern pharmaceutical production.

Installation of prosthetic dental implants

Prosthetic dental implants must meet the highest standards of quality and flexibility. Because every dental implant is unique, product migration from one variant to another must be easy, fast and highly reliable.

-

Read More

During the feeding and precision assembly process, it is imperative to guarantee and maintain the flawless finishing of precision parts to avoid any risk of injury.

Advanced Technologies, a subsidiary of Dentsply Sirona, has created a flexible assembly machine to manufacture different types of denture implants.

Two Asycube 80s with platforms configured to properly route components; an Asycube 50 for feeding small screws; and an Asyril SmartSight intelligent vision system, which includes an intuitive HMI, easy communication with PLC, and seamless recipe management.

Installation of fiber optic connectors

The full range of Radiall optical connectors includes not only standard products, but also several customized items. That’s why Radiall constantly strives for greater flexibility in its automated assembly processes, allowing its operators to focus on more value-added tasks.

-

Read More

Designed for demanding applications where reliability and high performance are indispensable, Radiall fiber optic connectors must not be damaged during the assembly process.

Radiall has developed an in-house manufacturing system that is both flexible and collaborative to facilitate automated assembly of fiber optic connectors.

The system consists of two Asycube 80s (feeding the ferrule and the ferrule holder, respectively).

A collaborative YuMi® ABB robot takes two components and places them under a press for assembly.