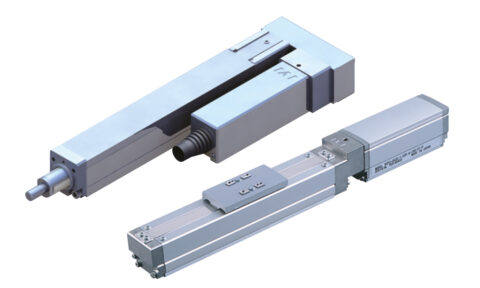

ERC3

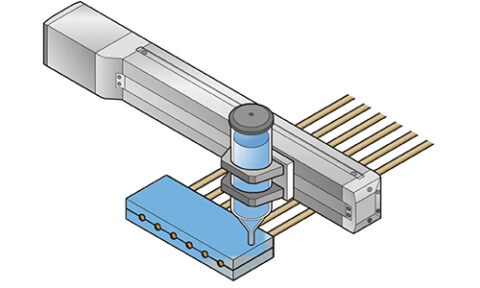

General Information

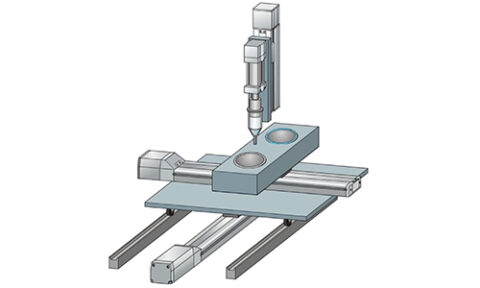

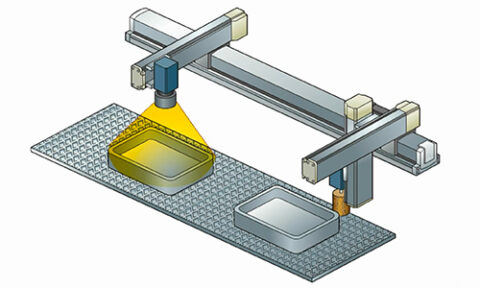

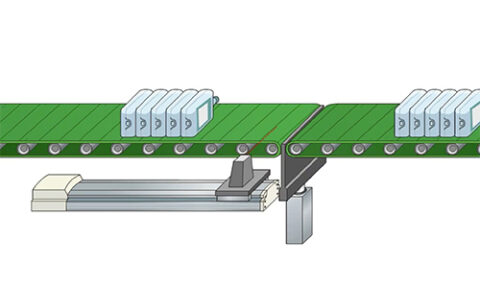

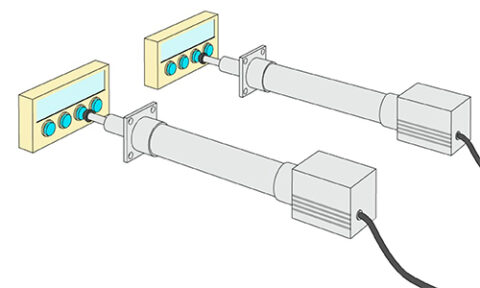

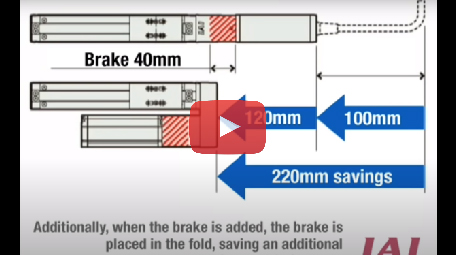

- No space is required for installing the controller, so the control panel can be made smaller

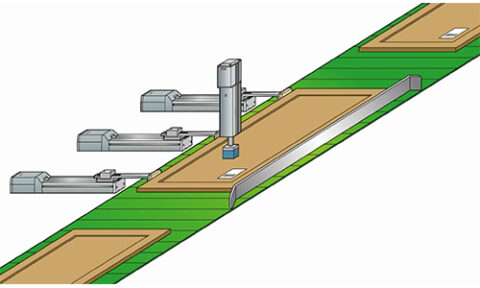

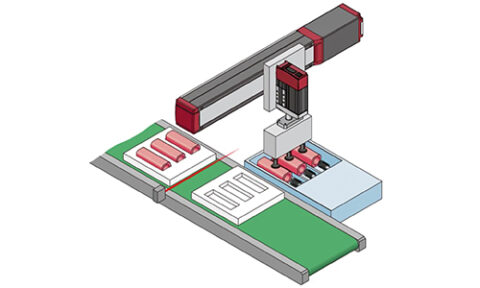

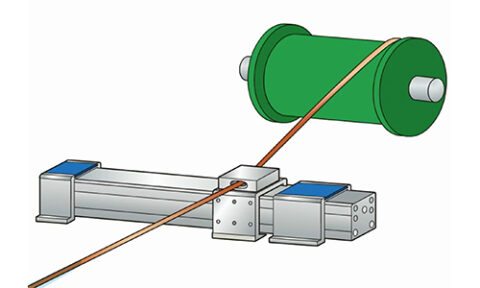

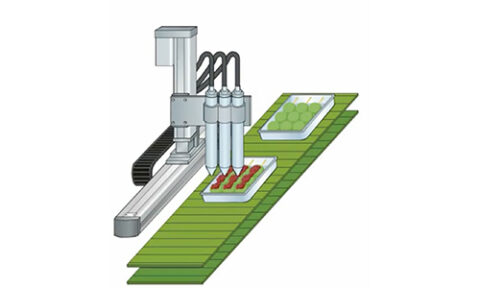

- 1.5 times the payload and maximum speed compared to ERC2 model

- 30% longer maximum standard stroke

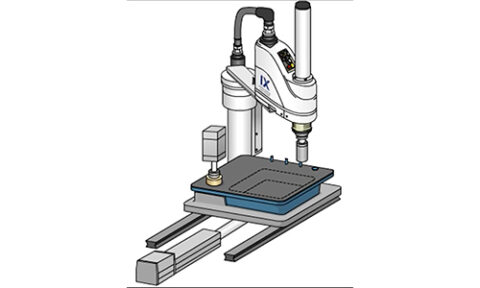

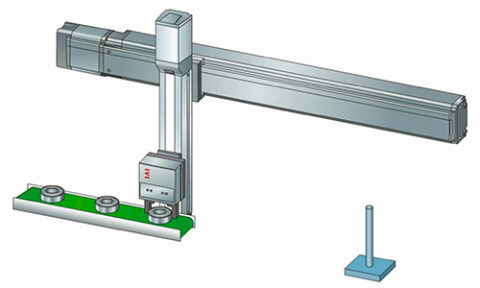

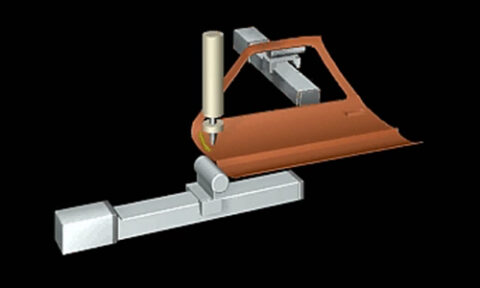

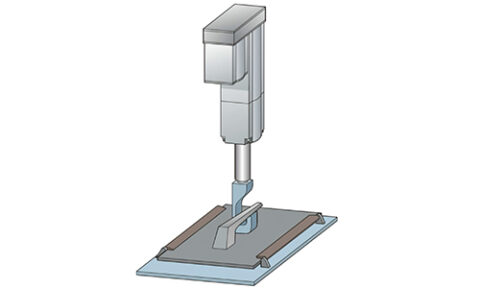

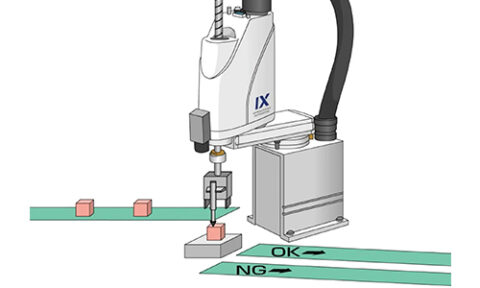

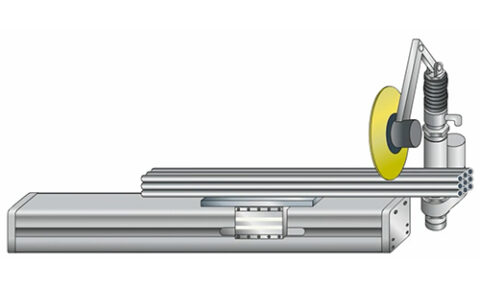

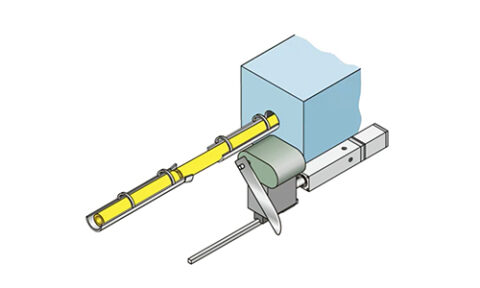

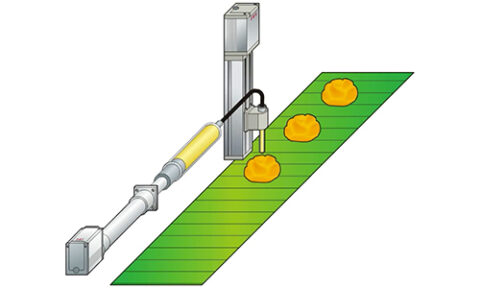

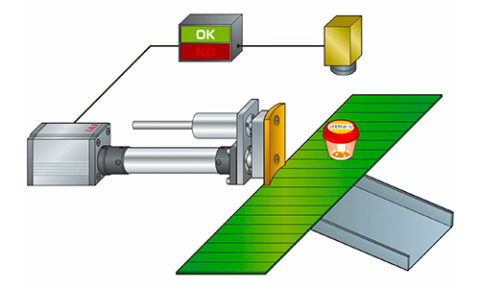

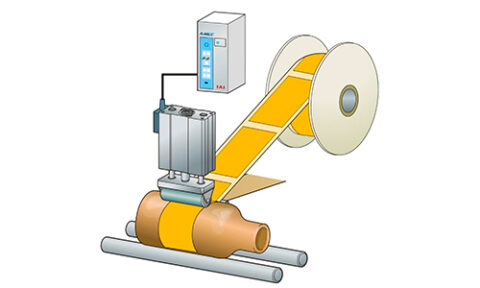

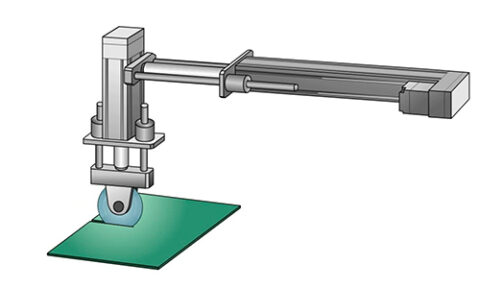

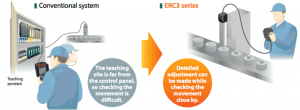

Teaching can be performed near the actuator

The teaching site is far from the control panel, so checking the movement is difficult. Detailed adjustment can be made while checking the movement close by.

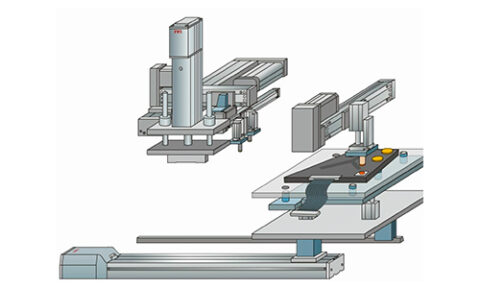

Built-in Controller Options

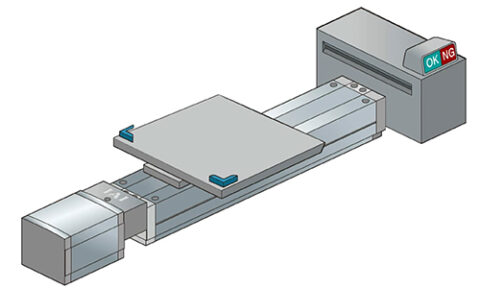

Two types of controllers are available for the ERC3: “CON” type and “MEC” type.

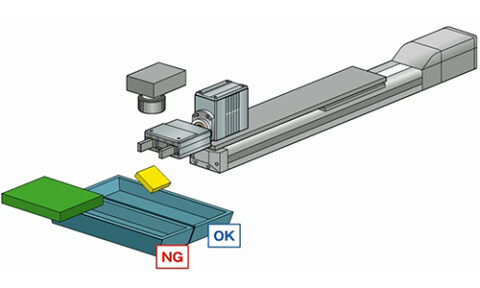

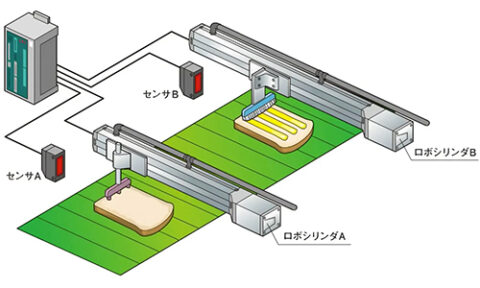

- MEC type is ideal if the actuator only needs to move through 2 or 3 points, just like an air cylinder. Operable only with the Quick Teach (optional) without a power-supply unit or PLC.

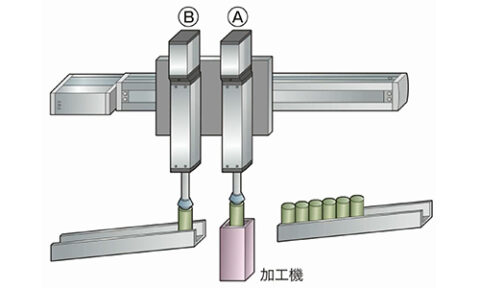

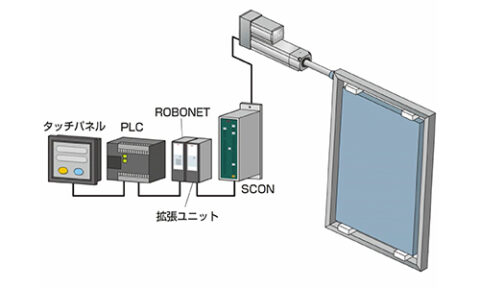

- CON type offers 16 positioning points under the standard specification, extendable up to 512 points when the PIO converter (optional) is used. Connectable to major field networks using the gateway unit.

Connection Methods

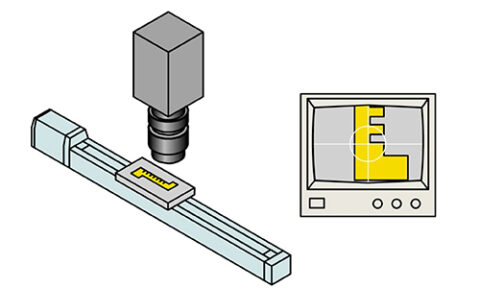

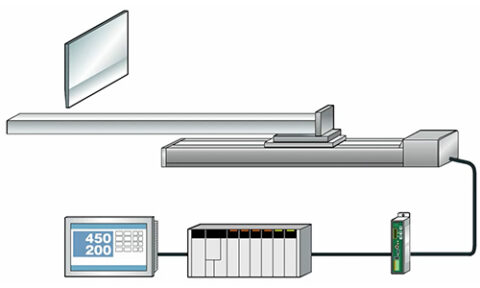

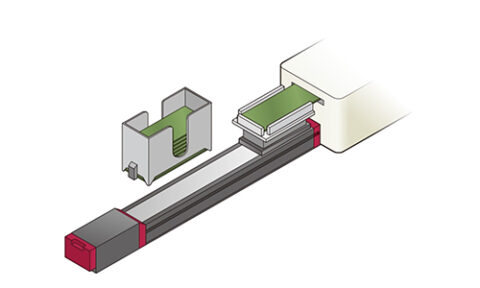

- Conventional Method: The ERC3 series can be connected to a PLC or other host device and controlled via PIOs and SIOs. Up to 16 positioning points are supported.

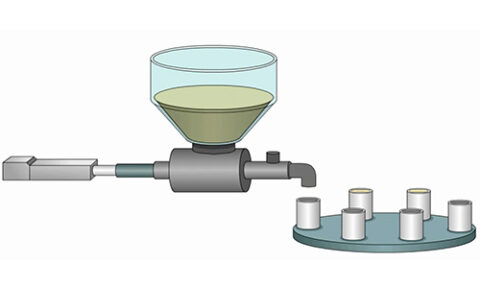

- PIO converter Method: Various functions offered by the ERC3’s built-in controller can be enhanced by connecting the PIO converter.

- All six PIO patterns will be supported and the maximum number of positioning points will increase to 512.

- The ERC3’s encoder can be operated in the simple absolute mode.

- The drive source can be cut off using the built-in relay (CV) or external relay (CVG).

- Calendar function can be used.

- Equipped with a brake release switch for the ERC3.

- Various statuses of the ERC3 can be checked in a simple mode.

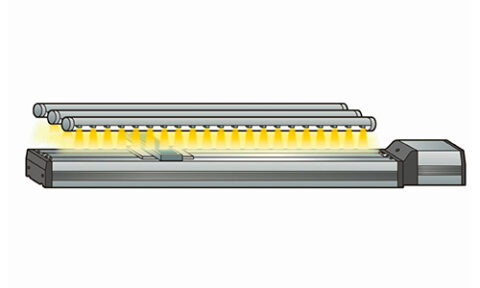

- Quick Teach Method: When the Quick Teach is connected, test runs can be performed without supplying power to the ERC3. Jogging, speed, acceleration and position adjustments can be made without an external 24V power supply.