Danikor

Flexible feeding systems automatically recognize and position parts of varying sizes and shapes, integrating them quickly and efficiently into assembly processes. Supported by robots and vision systems, they provide flexibility, speed, and cost advantages in production.

Wildermann Servo Press

Closed-loop controlled servo modules developed for high-precision assembly and forming processes. Offers 100% quality assurance through force and distance control.

ROKAE

Combining high precision, compact design, and powerful performance, Rokae 6-axis robots offer maximum efficiency in assembly, welding, machine feeding, and automation applications. Take your industrial production to the next level with Pulsar Robotics assurance.

Robotiq Gripper

No robotics knowledge is required to use Robotiq Grippers. You can install your gripper in minutes with Plug + Play gripper kits and use the software to program directly on the robot’s touchscreen.

Asyril Asyfill Smart Hopper

Revolutionizing part feeding, the Asyfill smart hopper completes Asyril’s intelligent solution. The combination of Asycube feeder, EYE+ smart control system and Asyfill ensures a high-performance flexible feeding process.

IAI Robotic Grippers

IAI'nin ürün yelpazesi, pick-and-place otomasyon sistemleri için geniş bir serbestçe programlanabilen tutma çözümlerini içerir. Üç işlevi bir arada sunarlar: tutma, ölçme ve test etme.

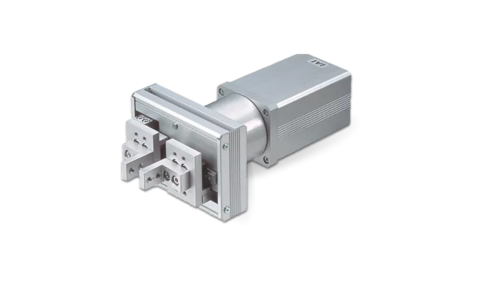

Asyril Eye+

EYE+ consists of a compact controller, a high resolution camera, a calibration plate and a power cable. This system allows the control of the hopper, the Asycube - our flexible feeder-, the camera and the robot via the EYE+ Studio web interface.

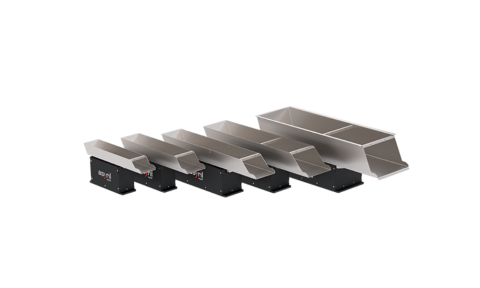

Asyril Asycube

It offers high-performance part feeding, pre-orientation, optimum surface distribution of cast parts and components.

Magnetic Actuators

They have very low coefficients of friction and therefore very high speed and acceleration, since they do not have any transmission organs such as gears, screws, belts, etc.