![]()

The challenge:

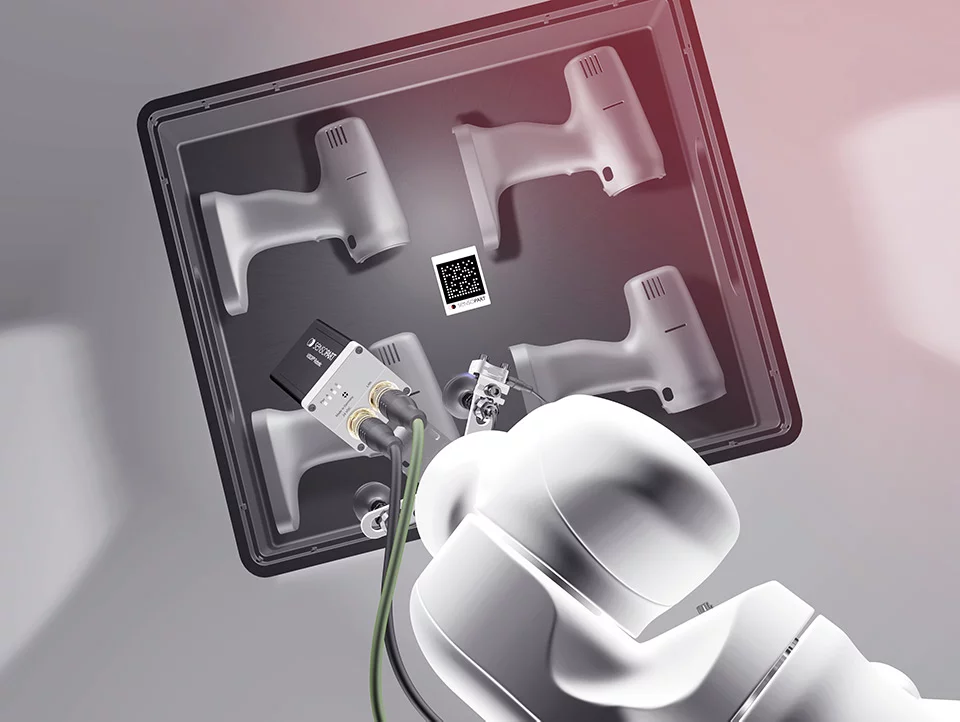

Components for the production process are supplied in load carriers. The challenge is to position the load carriers as precisely as possible, as this is imperative for a stable, robot-aided handling process.

Our solution:

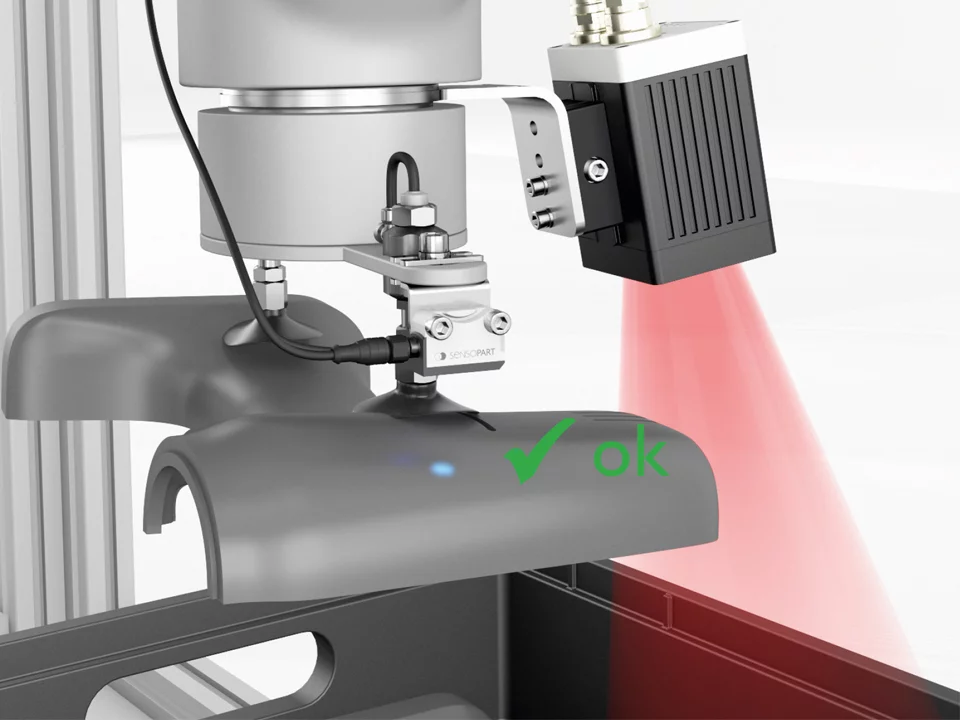

The VISOR® Robotic and Target Mark technology determine any inaccuracies in the position of the load carrier. Its position is then recalculated in the VISOR® and transferred to the robot in corrected form. This is achieved with the help of a special target mark fitted on the load carrier, whose 3D position is reliably and efficiently detected throughout the procedure. The robot uses this information to correct the pick-up points of all the components in the load carrier, thereby maintaining a stable process.

Your benefits:

- Considerable cost advantages due to the use of universal load carriers for all product versions, instead of special custom-made designs

- Greater flexibility due to the elimination of mechanical elements for immobilising and aligning parts

- High process reliability even when parts are inaccurately fed