![]()

The challenge:

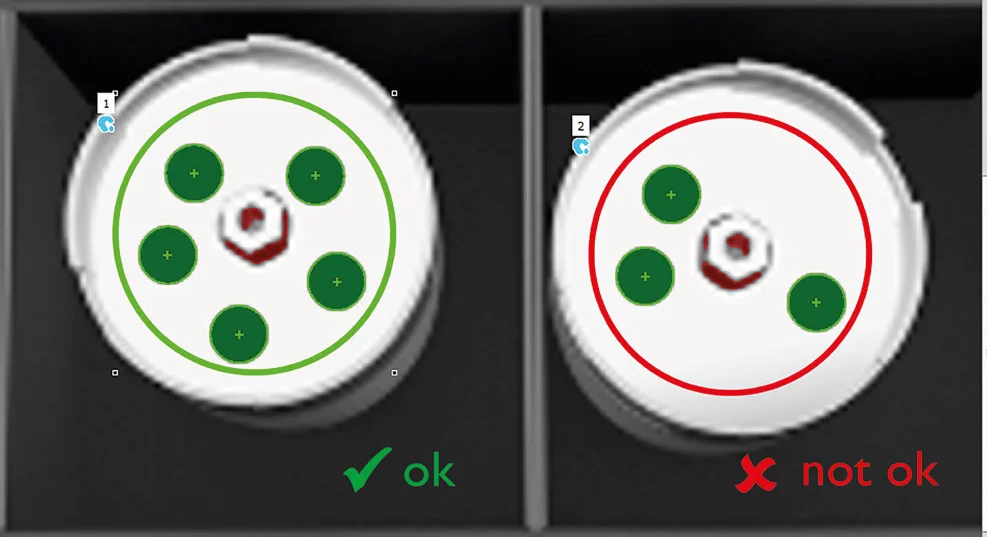

This process requires millimetre precision so that no spreading or smearing occurs when dispensing lubricants. Lubricant must be accurately applied in sufficient quantity to guarantee proper functioning. If too much lubricant is dispensed, malfunctions will occur. If carried out manually, errors can also result from the monotony of the task, caused by changing levels in the worker’s concentration.

Our solution:

Manual workstations can be easily semi-automated by using a VISOR® Robotic in combination with a cobot or industrial robot and an automated dispensing unit. The additional use of a BlueLight sensor enhances automation further, as it simply and reliably detects the presence of the load carrier. In this step, the VISOR® Robotic accurately locates components, and also allows inline inspection to check that the lubricant was successfully applied. With Industry 4.0 technology built in, it allows the saving of images and process data directly to a central location.

Your benefits:

- No smearing thanks to high repeatability, thereby guaranteeing high product quality

- Employees can be used for more value-adding work

- Fast implementation, as no special mechanical modifications are necessary