UV (Ultraviolet) light has a wavelength of 100-400 nm and cannot be perceived by the human eye. However, it has important applications in many sectors such as medicine, chemistry, automotive and food. Sensopart UV technology takes quality control processes to the next level by using the unique advantages offered by UV light in the field of industrial image processing.

Precise and Reliable Controls with UV Light

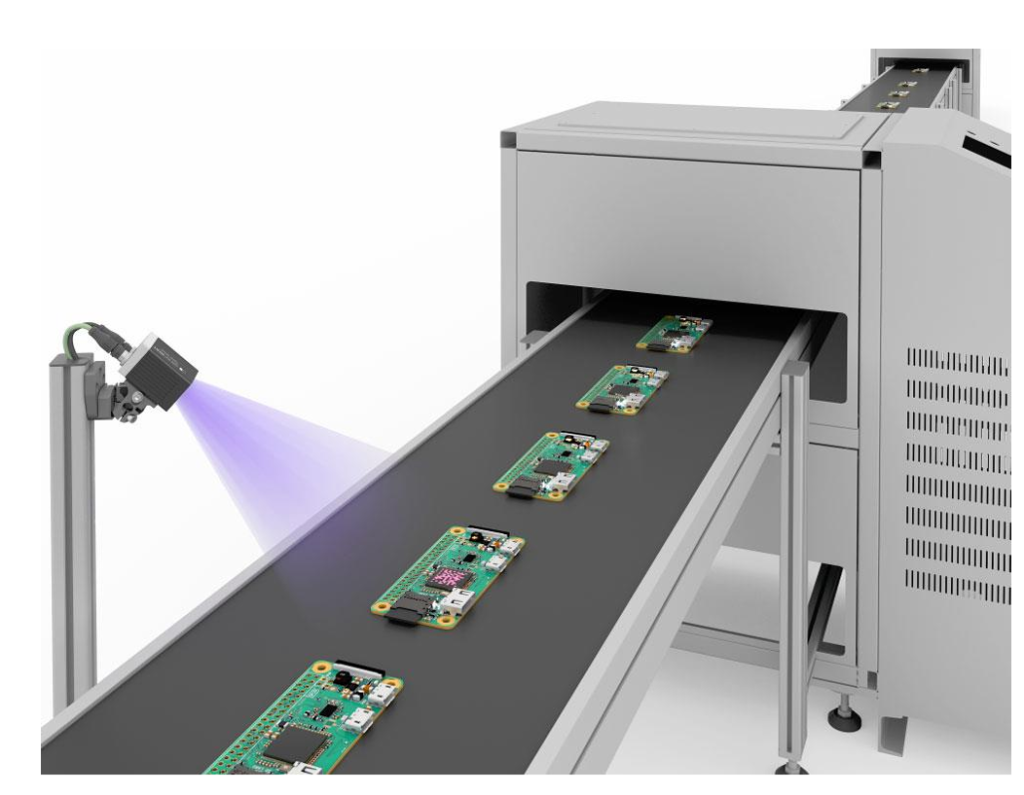

In many production processes, UV light is used to control details that cannot be detected by the human eye. For example; inks, adhesives or special markings containing luminescent substances become visible only under UV light. Sensopart image processing sensors, which are among our products, help to minimize production errors by providing precise and reliable controls in such applications.

Automated Inspections with Sensopart UV Camera

Sensopart’s UV cameras have been developed to detect invisible details. Thanks to the integrated UV illumination system, it eliminates the need for additional external filters and light sources, providing cost advantages. Many applications such as the control of particles in UV-sensitive liquids and ink controls that are only visible under UV light are made possible with this technology.

Advanced Image Processing Features

Sensopart Visor is an image processing sensor with integrated UV illumination and offers high resolution options:

- V20 Model: 1440 x 1080 pixels,

- V50 Model: 2560 x 1936 pixels

The camera can be selected in monochrome or color. The color version increases detection reliability by optimizing the contrast between the background and the marker. It also reduces additional costs by filtering images according to color channels without the need for external color filters.

Flexible Use with Different Lens Options

Sensopart Visor offers three lens options to suit different applications:

- Narrow (Narrow Angle Lens)

- Medium (Medium Angle Lens)

- Wide (Wide Angle Lens)

These options provide the most suitable field of view and ease of installation according to field conditions. In narrow and closed areas, camera placement is made more efficient with the appropriate lens selection.

Sharp Images with Auto Focus

Obtaining clear and accurate images is of critical importance in inspections performed with UV light. Sensopart Visor provides great convenience to operators thanks to its automatic focus adjustment. It becomes possible to obtain the sharpest and clearest image by focusing on the object within the field of view.

Flexible Lighting Control

Sensopart image processing systems offer the possibility of light management in different combinations with 8 integrated LED lighting. In this way:

- The amount of lighting can be increased or decreased.

- Light direction can be made by targeting certain areas.

These features increase the success of inspection processes by providing optimum lighting conditions on different surfaces and materials.

More Accurate Results with Extra Filtering Methods

Sensopart Visor highlights critical points using special filtering methods during image processing, thus providing a more reliable and stable quality control process.

Versatile Usage Areas

Sensopart Visor can be integrated not only for UV light controls but also in many different industrial applications with its LED lighting mode:

- Object counting

- Presence-absence control

- Measurement

- Barcode and Data Matrix code reading

- OCR (Optical Character Recognition)

Superior Quality Control with Sensopart UV Technology

Sensopart image processing sensors make a difference in the field of industrial image processing with their precise detection, cost advantage and automated processes. Thanks to their high resolution, integrated lighting and advanced filtering features, they capture even the smallest details clearly and minimize production errors.

Visit our website to learn more about Sensopart Visor and watch application videos.