Pulsar Robotik A.Ş., with its 30 years of experience in the sector, added a new product to its high-tech product groups and combined its experience with the Panasonic brand. As of 2014, Pulsar Robotics is the sole authorized distributor and technical officer of Panasonic Image Processing systems in Turkey. As a result of this technology partnership, Panasonic Image Processing Systems made a rapid entry into the sector with its easy use, superior features, compact structure and competitive market policy.

With the image processing systems it has developed since 1987, Panasonic takes a leading position in image processing as it does in many other sectors. Panasonic Image Processing Systems; can be examined under four main headings: camera, control unit, lens and lighting systems. Solutions are made with the combinations selected from these titles according to the environment characteristics and the required function. Panasonic Image Processing Systems are control unit-based systems and do not need a PC in any way during programming or operation. A large number of ready-made functions embedded in the control unit are sufficient to reach the solution. The system comes with a sufficient number of digital inputs/outputs, ethernet port, SD card slot and operator control.

During programming, it is sufficient to simply connect to any monitor. Programming is done with the operator control. After the programming is finished, the application can be followed on the screen, but it does not need a screen for operation. If desired, the control unit can save the work with an SD card to be mounted on itself or transfer it to an external device via the ethernet port. Applications can also be controlled via the digital input/output ports on the control unit. It is possible to make changes to the program even while the system is running on the production line.

Camera systems, which we encounter at the intersection of quality control and production, have become the eyes of automation systems and robotic units, so to speak. Panasonic Image Processing Systems, features such as product control, location information, size measurement, character reading and barcode reading increase the quality of the automation system, accelerate production and eliminate the need for operators in the system.

Pulsar Robotik A.Ş. also supplies a wide range of LED lighting systems to its customers.

Application Examples

1.Application

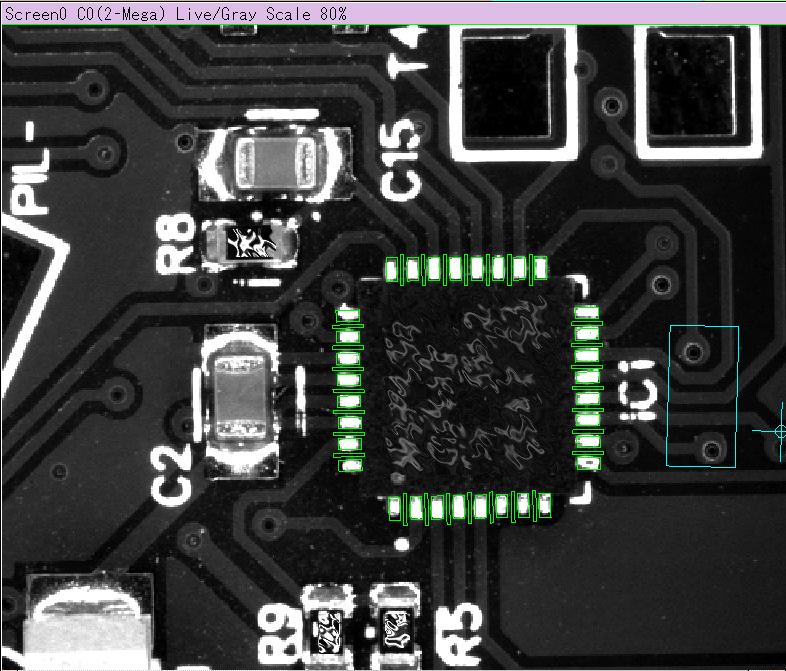

Subject: Electronic Circuit Solder Control

Equipment Used: PV200 + 2MP Greyscale camera + 25mm lens + Low Angle Ring Light

Application: Soldering control of silicon chip legs on electronic circuit is desired. During the control, it is requested to check both the correctness of the applied solder amount and whether there is a short circuit between the solders. Connector Binary Window function is used for these controls.

Sample number 1 – (Witness sample)

Sample number 2 – (Faulty sample)

Deneme sonucunda alt bacaklardan birindeki lehim miktarının yetersiz olduğu, sağdaki iki bacağın arasında ise kısa devre yaratacak lehim bulunduğu tespit edilmiştir.

2.Application

Subject: Stacking Tilt Control

Equipment Used: PV200 + 0.3MP Greyscale camera (2 adet) + 8mm lens (2 adet)

Application: It is required to measure the lying amount of 6 white goods boxes stacked on top of each other during the day. The company performs this test constantly using different products and packaging methods. The requested application is to transfer the difference between the positions of the machine seen in the lower camera and the machine seen in the upper camera to the system in mm, by placing a total of 4 cameras from both directions at the top and bottom of the tower. The Smart Edge (Line) function is used for the application. The green square seen on the screen scans from top to bottom and measures the distance between the first defined edge it finds and the point where the scanning starts. The difference between the two measurements gives the desired tilt value.

3.Application

Subject: Flare Control of Busbar Rings

Equipment Used: PV200 + 2 Greyscale camera + 16mm lens + High Angle Ring Light

Application: One side of the rings used in the production of the company is countersunk. With the Image Processing System, the countersunk side should be found and OK information should be sent to the Scara robot. In the application, the difference of refractive indices between countersunk and non-flared is used. Products with the correct index are marked as OK and the correct product is assembled by sending information to the robot via digital output. In total, this process is completed in less than 100ms.