What is Metal Bonder Structural Adhesive?

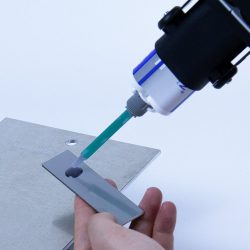

In addition to traditional fastening methods such as bolts, rivets and welding, bonding is also an accepted joining technique. Metal adhesive is a natural or synthetic substance used to join or bond two or more metal surfaces with a bond that is strong and flexible enough to resist separation without the need for conventional methods such as nails and screws.

What Should Be Considered When Choosing Metal Bonder Structural Adhesive?

In order to achieve the best results, it is necessary to use the metal adhesive that is most compatible with the material to be fixed. So there are some additional factors to consider before deciding on the use of adhesive. For example, the adhesive must be suitable for the materials to be bonded, match the manufacturing method, withstand the calculated working loads and the working environment. In addition, surface preparation, application method, curing system and their time and costs should also be considered.

Materials Using Metal Adhesives Together

The materials with which metal adhesives are used are given in the table below.

| Steel | Zinc | Ferrite | Aluminum | Polyester | Pine | Copper |

| Chromium | Rigid PVC | Wooden | Acrylic | Stainless Steel | Mirror | Marble |

| Nickel | Rock | Rice | Concrete | ABS | Epoxy FRP | Phenolic FRP |

What are the Effective Metal Bonding Methods?

Metals are easily bonded with various adhesives. Some of the most used and most effective metal bonding methods;

- Acrylic structural adhesives

- Anaerobic adhesives

- Cyanoacrylate adhesives

- UV adhesives

- Epoxy adhesives

- Silicone-based adhesives

What is Acrylic Structural Adhesive?

Acrylic is a type of acid that has a pungent odor (with exceptions as in Adhetron 1E1), is colorless, and is formed by the oxidation of “acrolic”. Polymers formed by prolonged exposure of this type of acid to heat, light or metals are also called ‘acrylic’. The molecular formula of acrylic is CH2=CHCOOH.

Acrylic adhesives are ready-to-use acrylic dispersion-based type adhesives. They bond metal, glass, wood, ceramics, ferrite and some plastics to form a high-strength permanent bond with high impact, tensile and tensile strength. They have wide temperature resistance (-50, +220 °C). If acrylic adhesives are used at temperatures well above the mentioned temperatures, deterioration may occur and they may also be flammable.

Acrylic structural adhesives cure with activator at room temperature. Depending on the type of adhesive, the adhesive and activator can be applied separately to the surfaces to be bonded or mixed in a static mixer just before application. Adhesive and activator should always be applied separately. When the two parts come into contact with each other, the adhesive begins to cure. There are also acrylic adhesives where the adhesive and activator have the same consistency. These are two-component systems and the adhesive and activator are applied side by side or in overlapping strips. While joining the parts to be bonded, the adhesive is also mixed. A static mixer can also be used if the mixed adhesive can stand for 5 minutes or longer. The advantage of using glue pre-mixed by a static mixer,

The general characteristics of acrylic adhesives are:

- Very high shear and tensile strength

- Good peel strength for PC-PAs, metals and plastics

- High impact strength

- Wide operating temperature range

- Able to use almost all materials

- High gap-filling ability (especially premixed acrylic adhesives)

- High resistance to environmental conditions,

- High resistance to humid environments

Advantages of Adhetron Structural Metal Adhesives Compared to Other Methods

| Other Acrylic Based Adhesives | Adhetron Metal Adhesives |

| Two-component adhesives that are liquid and used with activators have external mixing and/or very precise mixing ratios. | Adhetron metal adhesives do not require mixing. Mixer tips can be used in very sensitive situations, but these tips do not cause small losses that will affect the material consumption. |

| Epoxy Based Adhesives | Adhetron Metal Adhesives |

| Preliminary preparation is required on the surfaces to be connected. In addition, it is necessary to mix the hardener and adhesive materials used very well. Temperature and impact strengths are weak. | Adhetron metal adhesives are strong adhesives and do not require prior surface preparation. Mixing ratios are not very important. They have very good temperature and impact strength |

| Rivet | Adhetron Metal Adhesives |

| There is intense labor and material destruction. | Adhetron metal adhesives are easily applied without requiring special labor. It does not harm the material. |

| Welding | Adhetron Metal Adhesives |

| Spot welds and spots made on the front surfaces both damage the material and create visual disturbances. After the welding process, deburring, repainting and coating is done. | Adhetron structural metal adhesives do not damage the applied surface. It can be used easily even on previously coated or painted surfaces. |

| Tensol and Chloroform | Adhetron Metal Adhesives |

| They are used in the connections of polycarbonate and acrylic type materials with each other. However, they cannot be used in connection with metal, wood and other materials. The vapor they emit is highly carcinogenic. | Adhetron metal adhesives can bond acrylic type materials with any other material. |

| Adhesive Tapes (Double Sided) | Adhetron Structural Adhesives |

| They perform a holding rate depending on the cleanliness of the surfaces used. They are not heat resistant. Calibration cannot be performed after pasting. | Adhetron metal adhesives are heat resistant and calibrated. |

Adhetron Structural Metal Adhesive Products

You can safely use the structural metal adhesive products of the Adhetron brand that we offer as Pulsar Kimya.

The newest and strongest acrylic-based chemical adhesive in the Adhetron product family. It is a structural adhesive with high performance thermal resistance and high resistance to impacts.

It is an acrylic-based chemical adhesive product with strong adhesion and wide usage network.

Adhetron Acry’tron MMA 715 is an acrylic two component adhesive. It is suitable for all kinds of metal, plastic, composite bonding.

Acry’tron 008 HT is a premium structural adhesive material. It is an acrylic-based adhesive with increased resistance to high temperatures.