What is a Sealing Gasket? What Does It Do?

Sealing gaskets are the elements that play the role of combining between different installation and machine parts in order to prevent leakage in general. The gasket provides the sealing with the compression process. Sealing is possible with the harmonious operation of all components in the system.

Gasket Types Used in Sealing Applications

The sealing gasket is included in the class of static sealing elements and is used to prevent leakage between two stationary elements. According to the working principle of static sealing elements, we can divide them into two classes;

- Elements whose sealing effect depends on the compression ratio (gaskets),

- Elements whose behavior changes in response to pressure, they put more pressure on the surface as the pressure increases (O-ring, U-ring)

Gaskets are available in many types and liquid gaskets used in sealing applications will be mentioned.

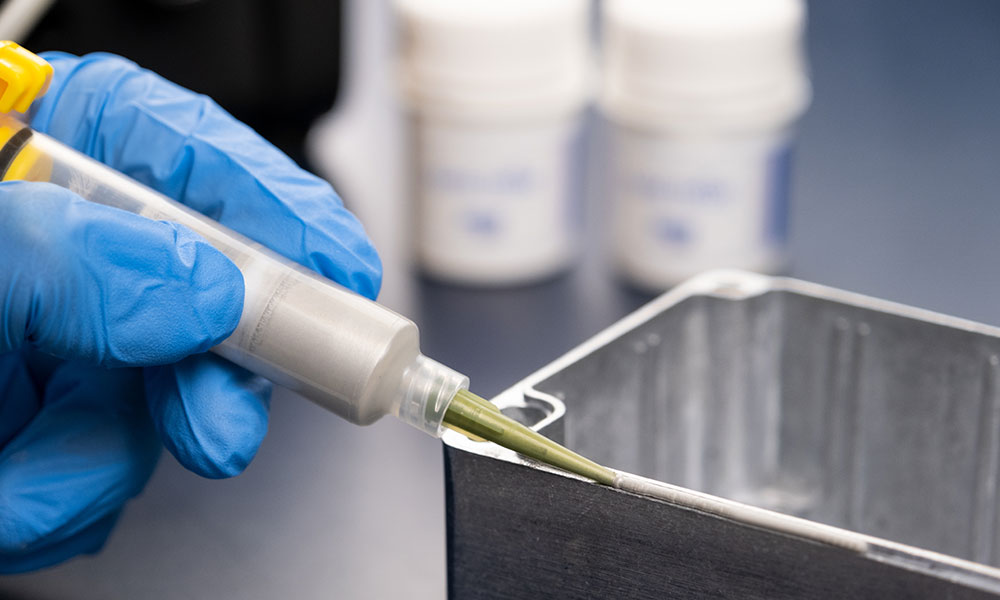

Liquid Gaskets in Sealing Applications

Liquid gaskets and form in place gaskets (FIPG) are functionally used to provide sealing between connection surfaces. The advantages of liquid gaskets over other gaskets are that they can withstand high temperatures and can also be used as an adhesive. It is also used to prevent liquid or gas leaks, especially in the application area. It hardens by itself at ambient temperature.

In addition to the liquid seals used in sealing applications, EMI/RF conductive seals are also used in the electronics industry. It is important to protect modern electronic equipment and filters from electromagnetic interference (EMI) and radio frequency interference (RFI) radiated by electrical circuits. Although this can affect the performance of the equipment, it can be easily eliminated by using a gasket made of conductive or absorbent material. Electronic devices must also shield themselves from external interference, which can be brought about by the correct use of an EMI/RFI conductive seal. These liquid seals are very special products (silver, carbon, nickel, etc.) supplemented with electrically conductive materials.

Where are Liquid Gaskets Used in Sealing Applications?

Liquid seals are very popular in many sectors, especially in the petrochemical, defense industry, aviation and automotive sectors. It is especially preferred where equipment such as motor, gearbox, pump, valve and mechanical connections and flanges are used.

Sealing Gasket Types Offered by Pulsar Kimya

The most important features of the products listed below in Pulsar Kimya’s portfolio are that they are non-hardening and non-freezing. They have the ability to work in a wide temperature range. They are produced to be resistant to all kinds of oil, grease, fuel oil, gas and similar substances.

Our products;

- Lock’tron S1577: Lock’tron S1577 is a PTFE-based anaerobic sealant. It can withstand up to 350 bar pressure when fully cured.

- UV-SIL 3011: UV-SIL 3011 is a low-viscosity, silicone-based sealing and coating material that is cured by UV and humidity in the air.

- UV-SIL 3022: UV-SIL RTV3022 medium viscosity, UV-SIL RTV3022 Used for filling and protective coating in electronic circuits.

- Hylomar M: With its non-hardening and non-drying material structure, Hylomar M is one of the most preferred sealing pastes in the business lines it is used in.

- Hylomar Universal Blue: It is a non-hardening, non-drying sealing paste. It is resistant to fuel oil, oil and refrigerant gases. It has unlimited assembly time. It can be applied on different gaskets and can be used for sealing problematic threads.

- Hylomar Aerograde: Non-hardening, non-drying sealant formulated for the aerospace industry. It is a Rolls-Royce and NATO approved sealant.

- Hylomar Advanced Formulation HV: Hylomar Advanced Formulation HV is a high viscosity non-hardening and non-drying sealant.

- 331 Joint Liquid: It is a PTFE (teflon) based sealing and loosening product. It gives excellent results in hydraulic, pneumatic and heating pipes. Its chemical resistance is very high.

- 333 Porajoint: It is a semi-flexible sealing preparation. It has very strong adhesion strength. It is suitable for use on all kinds of flanges and gears

In addition, our EMI/RF sealing products are;

- ELTECH 255SI: It is a two-component, solvent-free silicone-based flexible electrically conductive sealing paste filled with silver-plated aluminum and pure silver mixture.

- EL-TECH 230He: It is an epoxy-based, two-component electrically conductive adhesive paste with silver content and excellent conductivity.

- EL-TECH 235: It is a two-component electrically conductive adhesive paste with a silver content that can cure at room temperature.

How to Use Sealing Gaskets?

Pulsar Chemical Industry and Trade Inc. The method of use of the products offered to the service of consumers is very simple and effortless. After cleaning the surface to be applied, the product should be applied to the surface uninterruptedly without the need for any processing.