What are Electrically Conductive Adhesives?

Electrically conductive adhesives are primarily used for electronic applications where the circuit elements are held in place and the electric current formed between them can be transmitted. Conductive adhesives gain conductive properties thanks to the mixture of metals such as silver, gold, copper, nickel, graphite and chemical resins. Unlike electrically conductive adhesives, most common adhesives (anaerobic adhesives, cyanoacrylate adhesives, epoxy adhesives, and acrylic-based adhesives) act as an electrical insulator.

In the electronics industry, some heat-sensitive electronic components cannot be soldered, the intense heat of a liquid soldering furnace or soldering iron can damage the circuit elements. Such applications require the bonding of electronic components and the use of an electrically conductive adhesive as an alternative to the soldering. Conductive adhesives are generally chemical resistant, non-deforming and friction resistant products.

Silver Filled Conductive Adhesives

They are electrically conductive silver filled materials. Silver conductive adhesives can be cured at room temperature or by baking. There are also single or double component varieties. Two-component conductive adhesives are made ready for use by mixing process within the scope of the determined ratio.

Silver filled conductive adhesives have excellent electrical conductivity, adhesion and chemical stability. After the adhesive is applied to the surface and cured, the silver particles in it bind to each other and provide conductivity.

Silver conductive adhesives are available in different containers. The adhesive is easy to apply and if stored properly, they can last a long time and allow for reuse.

It can adhere to metals, plastics (kapton, mylar etc.), composites, silicones and even gold/gold plated surfaces. Does not require any primer.

Where are Electrically Conductive Adhesives Used?

Applications for electrically conductive adhesives; It is not limited to bonding or placing components (circuit elements) on PCBs, it is also used to provide conductivity in flexible circuits. For example, it is used in touch panels, LCD screens, RFID systems, coating and bonding of the conductive parts of reader tags and antennas, and flexible keypads (membrane switches).

It is used as an adhesive material in microelectronic components, in the encapsulation manufacturing process, and for many other purposes.

Electrically conductive adhesives and paints/coatings are the safest choice for providing EMI/RF shielding, which is the method applied to prevent electromagnetic interference. It is mainly preferred in the defense industry, automotive, medical, space, aviation, maritime and telecommunication sectors. Aim; It is to protect the coated or bonded surfaces against unwanted magnetic fields.

How Are Electrically Conductive Adhesives Applied?

Electrically conductive adhesives are supplied as single or double component. In two-component adhesives, it is mixed homogeneously by taking it into a container in the determined proportions and enough to be used, and applied to the surface to be applied.

Pulsar Chem. Conductive Adhesive Solutions

As Pulsar Chem, our product range includes electrically conductive adhesive types. You can contact us to offer special solutions for your applications and to recommend the right product for you.

EL-TECH 142 is a silver-filled, electrically conductive paint/coating that can be used on hard and flexible surfaces, resistant to chemicals, and can be cured by oven at low temperatures. Creates an EMI/RFI shield.

EL-TECH 152 is one component, silver filled, electrically conductive, flexible coating that can be manually applied via screen printing, dipping or syringe.

EL-TECH 230He is a silver filled, heat cure epoxy based two component electrically conductive adhesive with excellent conductivity.

EL-TECH 235 is a two-component electrically conductive adhesive that can be cure at room temperature and is preferred for bonding heat-sensitive components. It is silver filled. Creates an EMI/RFI shield.

EL-TECH 245 is a silver filled, one component flexible electrically conductive adhesive. It is cured by heat cure at very low temperatures.

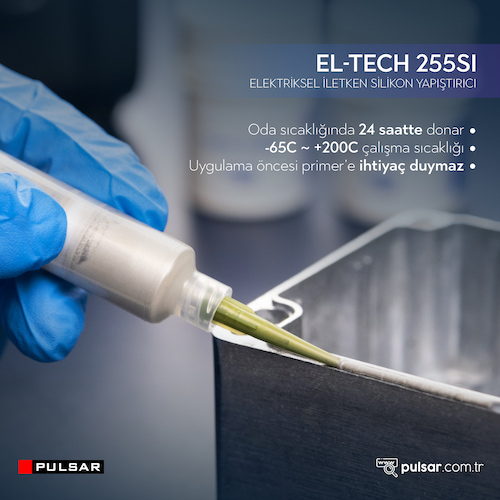

ELTECH 255SI is a two-component, solvent-free silicone-based flexible adhesive and sealant filled with silver-coated aluminum and silver mixture.