Greasing and Lubricating

Lubricating:

We have already talked about the fact that corrosion is a major problem for all equipments. One of the reasons of corrosion is the static electrical charge.

Equipment filled with static electric will create a serious security hazard by creating an arc jumping via attracting all the particles on him like a magnet. We can encounter this problem in the flange connection points of all type of pipe setup that has solid, liquid or gas flow inside.

In these cases, we require a product that can lubricate, protect and grounding. With a product which can do all of these we will have done three operations in one, hence we will have seriously economise on terms of consumables and the labor power.

In multi-functional products like these, it is important for products to be certified (be documented). Chemical products that has the PMUC (Produits et Matériaux Utilisable en Centrale [in French]) (Products and Materials Used in Power Plants [in English]) accreditation must be used in industries with high danger class.

Other than flange connections, conveyors and wrapping machines are lubricated to avoid any stoppage that can disturb the production. It is beneficial to choose a product that does not attract dust or any other particles and performs dry lubrication.

Greasing:

In selection of greases the parameters like viscosity, additives, DN factor and the application quantity etc. are important. Moreover, criteria like dripping point, operating temperature and resistance against aggressive gas & liquids like hexane and heptane are important for the selection greases. It is necessary to choose the correct grease to increase the greasing period of equipment that are hard to reach.

Other than special situations mentioned above, it is better to choose products that contain special additives like molybdenum and lithium for equipment that work under heavy loads like gearbox, crank and flywheel (balance wheel). Sealing products like elastomer o-ring, pad (carpet/rug) and gasket are wearing off due to the liquid they are in contact with which may cause leaks in time. Systems that run out of oil (lubricant) faces the danger of wrapping. In these cases it is possible to protect the whole equipment by greasing the gasketing material with a special grease.

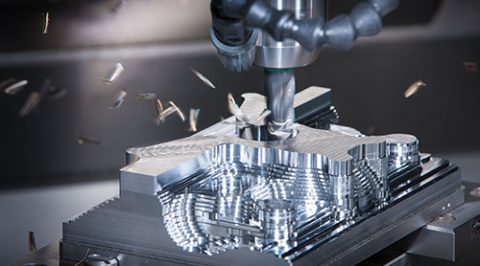

We can obtain a good performance and ease of application with a grease in form of spray and that attaches perfectly to surfaces of worn gear mills, hinges (joints/knuckles) and elastic (rubber) surfaces. In compressors that work with a high rotation like 10-15 rpm not every grease can attach to the mechanism. These equipment require a grease that can adhere itself in high rotations. These products are important for the safety and the stability of the system.

Otherwise, the grease that is scattered away due to the rotation speed will leave bearing (ball bearing) and the bearing shell (bearing house/bearing sleeve/roller track) unprotected. Damage can occur on the cages due to overheating and bearing marbles that fly off with high rotation speed can create serious hazard for the environment and the equipment or even cause a system lockdown.

For equipment that work underwater we have to opt to products which are resistant to water, steam and salty water. The most common mistake here is to use the same product for equipment which operates in an open area like crane that works with ropes and pulleys too. In these systems it is better to use an oil that can penetrate inside the rope. Similarly, in lubricating components like transfer chains preferring products that can penetrate to pins and gudgeons also are anti-static & anti-dusting will help us to obtain the best result.

Electrical equipment, electric motors, breakers (power switches), bougies (sparkplugs) and accumulators (batteries) need lubricating because of the similar reasons as the other equipment. Here, it is required to use products that have water-resistance and electrical conductivity.

Products that suit to the important points mentioned above are found in Pulsar Kimya’s portfolio.

Safety belt for critical and problematic equipment;

As you can understand from the introduction some equipment present critical importance. From time to time, these equipment have to continue to function (operate/work) under risky conditions due to the reasons like operating conditions, the age of the equipment, lack of maintenance service and not being able to supply the spare parts.

In these types of equipment using greases that allow the equipment to operate even if the crankcase (oil pan/oil sump) empties out and is formulised with nano particles will minimise the problems like friction, heating and wearing.

SIMILAR SOLUTIONS