Connection, Sealing, Gasketing and Adhesion

Each of these processes requires a specific solution within.

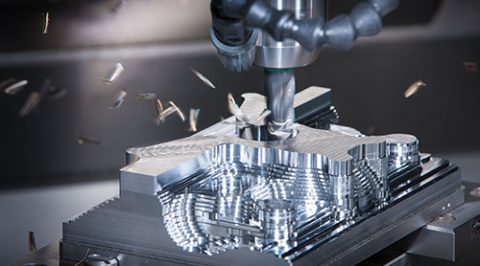

In connection processes, the criteria like the diameter of the parts which will receive the application, the temperature of the environment, application gaps, aggressive chemicals to be faced in the environment, dismantling torques and pressures etc. are important in the product selection.

Similarly, in gasketing applications, criteria like for product not to freeze, to be easily cleaned and to be resistant to high temperatures is important in the selection of product.

Applying the same anaerobic products to pins, crank pins and blind nuts that were applied to threaded pipes will not give the same result. In our portfolio there are chemical products that are resistant to temperatures from -250 degrees to 1500 degrees, to pressure up to 350 bar, to aggressive chemicals and unaffected from high vibrations.

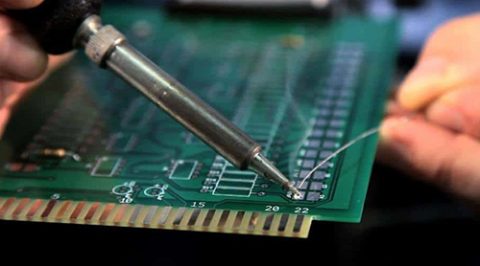

When choosing and adhesive paying attention to criteria like heat resistance, surface of the materials, gap between surfaces to be adhered (bonded/attached), the curing time etc. will help ease your selection process.

The properties of the surfaces to be adhered is one of the main points to be considered during the adhesion process. During the adhesion process we might have to deal with hard-to-stick surfaces like rubber, tyre, plastic, metal, silicone or PP/PE. Moreover, the different viscosity on vertical or horizontal surfaces and the curing period should be considered.

SIMILAR SOLUTIONS