Brown and White Goods Industry

White goods are machines that were produced in factories and called household appliances, which were generally white in appearance in the early days. Washing machine, refrigerator and cooker group products can be given as examples of this group. According to scientific research, it is an indicator of the development level of a society. Developed societies use a large number of white goods, while underdeveloped societies use less white goods.

In our country, the white goods sector started production as an assembly industry in the 1950s. The first product was produced in 1955 and the first Turkish-made refrigerator was launched in 1960. The Turkish white goods industry has recorded a very serious growth since then. The sector, which started with companies working within the scope of license agreements and then switched to the use of know-how, has achieved significant success in the world markets with its unique designs and the technology it uses today. Thanks to these features, it has become a sector that makes serious contributions to our country in terms of employment and exports, when the supplier industry manufacturers, which have become one of Turkey’s deep-rooted and dynamic sectors, are taken into account. The industry mainly consists of two sub-sectors; white goods (durable consumer goods) and small household appliances that dominate the sector. Turkey’s white goods industry is Europe’s largest and the world’s second largest production base after China. The sector contributed a great deal to the foreign trade balance of Turkey in 2019 by having a foreign trade surplus of approximately 3.8 billion USD. made a significant contribution to Turkey’s industrial power.

It is estimated that direct employment is approximately 60,000 people and this figure is 600,000 together with auxiliary industry companies, dealers, authorized services and call centers. Considering that the number of employment corresponds to a share of approximately 2.1% among all employees in Turkey, it can be said that one out of every 50 employees is in the white goods sector. The stakeholders of the sector can be summarized as approximately 500 SME-sized auxiliary industry companies, 15,000 retail sales points, and a service network providing 3,500 after-sales services. Considering this way, the size of the White Goods Production Ecosystem can be understood more clearly.

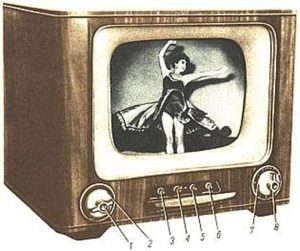

Brown products represent electronic products such as televisions, DVD players, stereos and home entertainment systems. The first brown goods, the Television, were invented in 1923 by John Logie Baird in the town of Hastings, UK. The first television image was also broadcast by Baird in 1926. Due to the inadequacy of plastic injection and molding technologies, the tone and feel of wood suitable for human nature, and the fact that it seems more suitable for home furniture, it has been put on the market by covering with wood or wood-like materials. For this reason, this sector, which we call consumer electronics today and offers a much wider product range compared to “White Goods”, was called brown goods in the early days. Below is an OT-1471 Belweder, a 1957 TV set.

According to TESID (TURKISH ELECTRONIC INDUSTRIALISTS ASSOCIATION) 2018 Almanac, the global consumer electronics market is expected to grow by 2.2% between 2017 and 2021, reaching $730.9 billion. The Turkish consumer electronics market, with a size of 9.8 billion dollars, constituted approximately 1.5% of the global consumer electronics market in 2017. Television production in this sector constitutes more than 20% of the total production and acts as a locomotive. The Turkish consumer electronics market, with a size of 9.8 billion dollars, constituted approximately 1.5% of the global consumer electronics market in 2017.

“Smart Products”, the number of which has increased rapidly in recent years with the developing technology, changing needs and the widespread use of internet technologies, has increased the use of embedded software or software that can be developed in both the White Goods and Brown Goods markets. With the emergence of smart TVs, cleaning robots, and remotely controlled heating/cooling systems in our homes today, White Goods and Brown Goods are produced in a more intricate manner, and in these devices, sub-electronics such as printed circuit board (PCB), touch screen, Bluetooth transmitter, which were not used before, systems are integrated into productions.

This situation has led to the development of both production methods and changes in production needs. With our product portfolio consisting of approximately 1400 items, Pulsar Kimya improves the production processes of cooker, washing, cooler and freezer class products with our solutions that will accelerate the production in the White Goods group, which is called durable consumer goods, to increase the speed of the product leaving the factory, reduce production waste, and extend the return processes of the product in the field. We are optimizing. With a similar logic, we approach consumer electronics production processes with the experience and knowledge we have gained in electronic components, defense electronics, professional and industrial device productions.

In this context, pre-applied bolt fasteners to eliminate vibration-induced loosening in all product groups for White Goods, high-temperature resistant structural adhesives in metal-metal and glass-metal, metal-plastic joining processes in intermediate production processes in cooker group products, elastic bonding solutions, sealing products, backing products. We are the solution partner of our customers with our anti-boiling products for the components that are required to be disassembled.

Products used for sealing or fixing of used gaskets and/or prolonging their service life in demolition group productions, structural bonding solutions, special retouching chemicals for inox materials, protective solutions for electronic components, products for anti-fogging systems for freezer and cooler group products, resistant to refrigerant gas resistant materials We offer chemical solutions to our customers with our products, food approval lubricants for in-product systems and many more.

In the Brown Goods product group, we provide solutions with functional chemicals such as electrically conductive adhesives, component fixing compounds, PCB cleaning products, conformal coatings and potting solutions, chemicals for creating EMI/RF shielding for special equipments, structural adhesives, magnet adhesive (ferrite bonder) products.